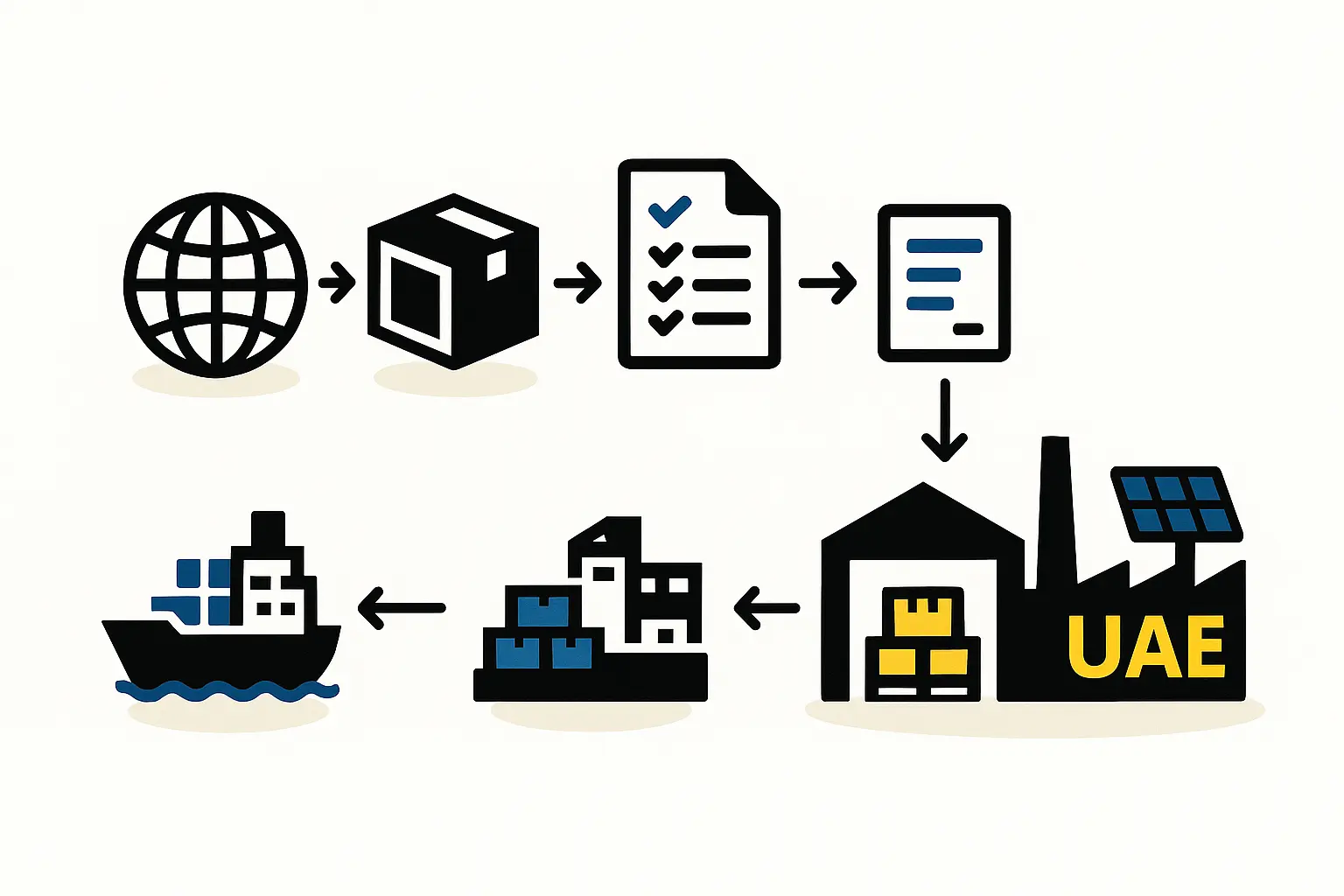

For an investor considering a solar module factory in the United Arab Emirates, the potential is immense, bolstered by government support for local industry, high demand for solar energy, and an ideal location.

Yet, a fundamental question quickly arises: for such a complex assembly, where do all the individual components come from? And how does one manage the logistics of getting them to a factory floor in Dubai or Abu Dhabi?

This article breaks down the raw material supply chain for a solar factory in the UAE, examining which materials are typically imported and which can be sourced locally, along with the logistical considerations for a smooth, cost-effective operation.

The Global Puzzle of Solar Manufacturing Components

A solar module is not a single product but an assembly of precision-engineered components sourced from around the globe. Understanding this global network is the first step in building a resilient supply chain.

For a new factory, the primary challenge is securing a reliable flow of these materials, each with its own set of suppliers, quality standards, and logistical paths.

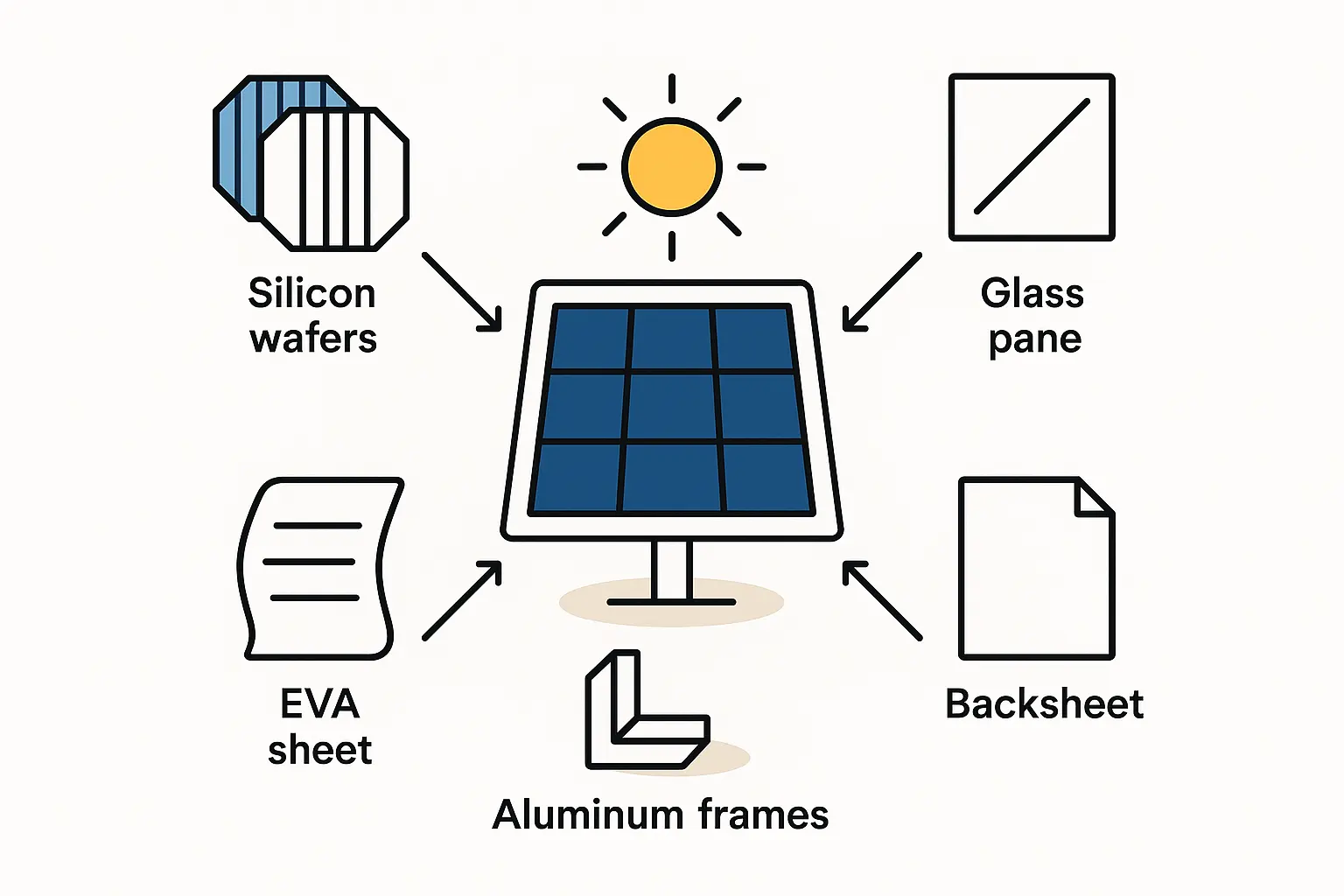

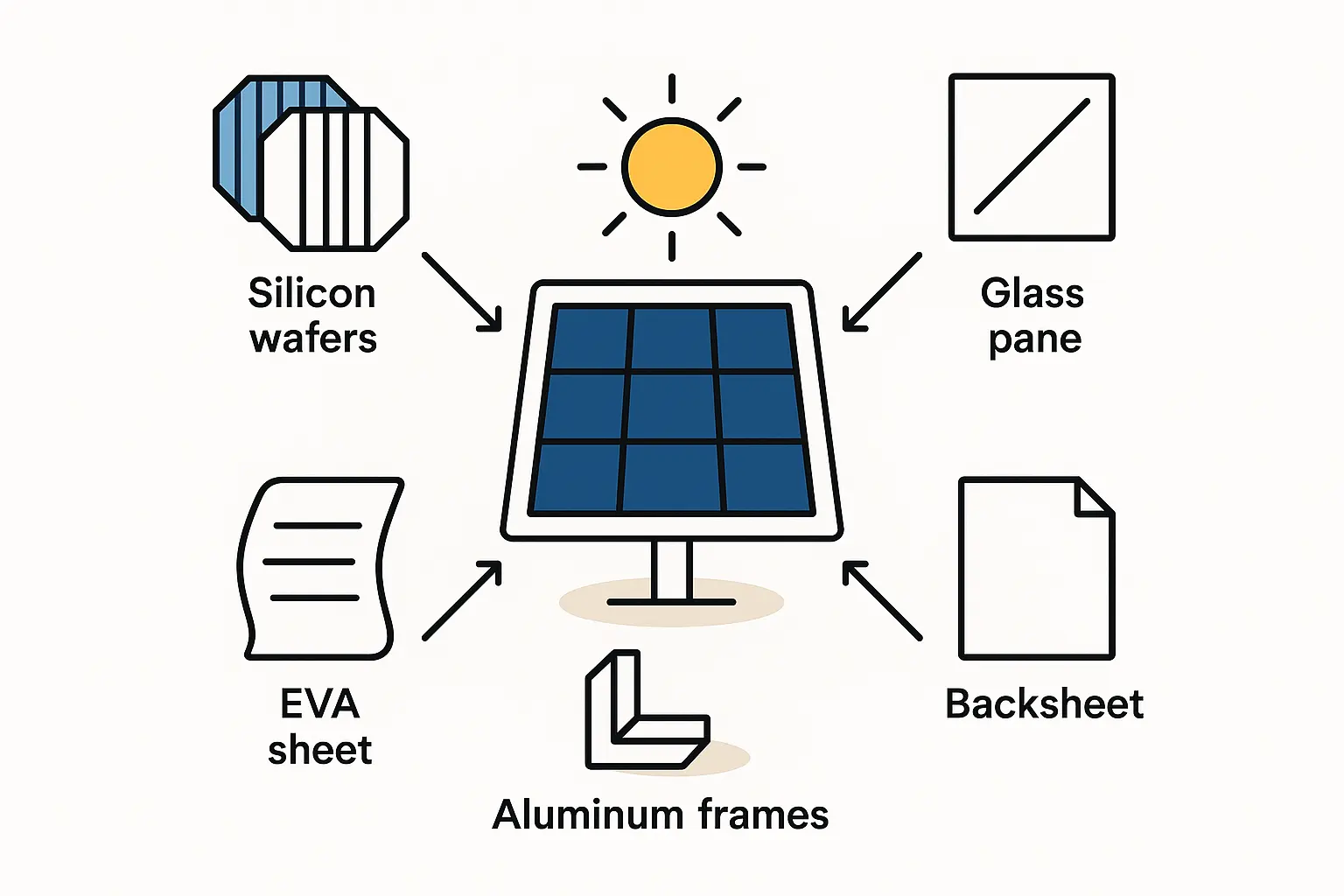

The main raw materials for a solar panel include:

- Silicon Wafers: The most critical and technologically sensitive part of the module.

- Solar Glass: Specially formulated, low-iron, tempered glass for the front surface.

- Encapsulant (EVA): Ethylene-vinyl acetate films that bind the layers together.

- Backsheet: A protective polymer-based layer for the rear of the module.

- Aluminum Frame: Provides structural integrity and mounting capability.

- Junction Box: Contains the diodes and output cables.

Orchestrating the procurement and delivery of these items is as crucial as the assembly process itself.

The UAE’s Strategic Advantage in Global Logistics

The UAE’s ambition to become a high-tech manufacturing hub is supported by world-class logistics infrastructure. This provides a significant competitive advantage for any import-dependent industry, including solar module assembly.

Key hubs like Jebel Ali Port in Dubai and Khalifa Port in Abu Dhabi are among the most efficient in the world, offering direct shipping routes to major manufacturing centers in Asia and Europe.

Government initiatives such as “Make it in the Emirates” bolster new industrial ventures with incentives and streamlined processes. Establishing a factory in a free zone like Jebel Ali Free Zone (JAFZA) or Khalifa Industrial Zone Abu Dhabi (KIZAD) offers further benefits, including exemptions from import duties on raw materials and machinery, which significantly simplifies the financial model.

A Practical Breakdown of Your Raw Material Supply Chain

While the UAE provides an excellent base of operations, the raw materials themselves come from a diverse set of international and local suppliers. A successful sourcing strategy must balance cost, quality, and supply security.

Silicon Wafers: The Heart of the Module

The silicon wafers that form the solar cells are the most technologically advanced component. Currently, the global market is dominated by producers in China, though high-quality wafers are also available from suppliers in Germany, South Korea, and Taiwan. For a new factory in the UAE, wafers will almost certainly be imported. This dependency makes strong supplier relationships and rigorous quality verification paramount as you navigate the solar module manufacturing process.

Solar Glass and Backsheets: The Protective Layers

Specialized solar-grade glass must be low-iron for maximum light transmission and tempered for durability. While the UAE has glass manufacturers, sourcing glass that meets the precise specifications for modern PV modules often requires importing from specialized suppliers in Asia or Europe.

Similarly, encapsulant films (EVA) and backsheets are almost entirely imported from established chemical and material science companies.

Aluminum Frames: The Local Sourcing Opportunity

This is where UAE-based manufacturing offers a major advantage. The country is home to one of the world’s largest premium aluminum producers, Emirates Global Aluminium (EGA), and a robust ecosystem of downstream extrusion companies.

As a result, a solar factory can source high-quality, custom-designed aluminum frames locally, which provides substantial benefits:

- Reduced Shipping Costs: Eliminates expensive and lengthy international freight.

- Shorter Lead Times: Allows for more flexible, just-in-time inventory management.

- Lower Risk: Reduces exposure to global shipping disruptions.

- Cost Control: Potentially lower unit costs and no import tariffs.

Leveraging the strong local aluminum industry is a key strategy for optimizing both cost and operational efficiency.

Junction Boxes and Consumables: The Finishing Touches

Junction boxes, diodes, cables, and other small consumables are typically sourced from specialized manufacturers in China or Europe. While they represent a smaller fraction of the total material cost, their quality is essential for the safety and long-term performance of the final product.

Navigating Costs, Timelines, and Supplier Reliability

A solid sourcing plan must be grounded in business practicalities, involving careful financial planning, logistical scheduling, and risk mitigation.

Planning for Lead Times and Shipping

Securing materials from international suppliers requires diligent planning. Ocean freight from East Asia to Jebel Ali Port, for example, typically takes between 20 and 30 days. This timeframe doesn’t account for production time at the supplier’s factory or potential delays in customs clearance.

A prudent business plan accounts for these timelines by maintaining a buffer stock of critical imported components, such as two to three months’ worth of wafers and EVA. This buffer is a key factor in the overall investment requirements for a solar factory.

The Critical Importance of Supplier Vetting

For an entrepreneur new to the industry, selecting reliable suppliers is one of the greatest challenges. A low price can be tempting, but it may hide issues with material quality, inconsistent supply, or poor documentation.

Experience from J.v.G. Technology turnkey projects shows that establishing a multi-stage quality gate for incoming materials is a cornerstone of long-term success. The vetting process for equipment suppliers and raw material producers should be rigorous and may include:

- Requesting and verifying material certifications (e.g., ISO, TÜV).

- Ordering samples for independent testing.

- Conducting remote or on-site factory audits where feasible.

- Implementing robust quality control steps for all incoming goods at your factory.

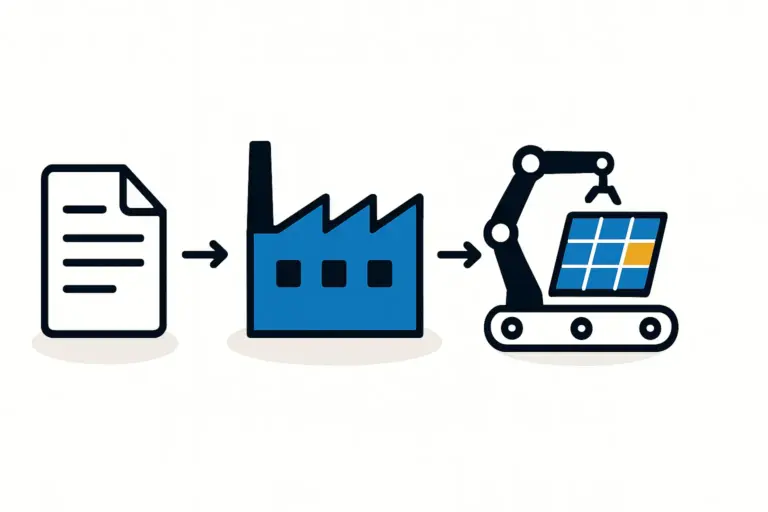

Assembling Your Supply Chain: A Phased Approach

Building a resilient supply chain is an iterative process. A practical approach is to start with a reliable, albeit smaller, group of vetted international suppliers for critical components like wafers and cells.

For materials like aluminum frames, establishing relationships with local UAE suppliers early on is a strategic priority.

For investors seeking a more streamlined entry, a turnkey solar production line solution often includes access to a pre-qualified network of material suppliers. This can significantly de-risk the initial procurement phase and allow the management team to focus on production and sales.

Frequently Asked Questions (FAQ)

Can I source all raw materials for a solar panel locally in the UAE?

Not at present. The UAE offers a strong local supply chain for aluminum frames, which is a significant advantage. However, core technological components like silicon wafers, solar cells, and specialized polymers (EVA, backsheets) are almost entirely imported from established global producers.

How do UAE free zones help with raw material imports?

Free zones like JAFZA and KIZAD are designed to facilitate manufacturing and trade. For a solar factory, the primary benefits are typically 0% corporate tax and, crucially, a 0% duty on imported goods and raw materials used in manufacturing within the zone. This provides a direct and substantial cost saving.

What is the biggest supply chain risk for a new factory?

The primary risk is ensuring consistent quality and reliability from international suppliers. A batch of substandard wafers or defective junction boxes can halt production and lead to significant financial loss. The second major risk is disruption to global shipping, which can cause unpredictable delays.

How much buffer stock should a new factory keep?

A common recommendation is to maintain an inventory of critical, long-lead-time imported materials (like wafers, glass, and EVA) sufficient for two to three months of production. This provides a cushion against shipping delays or unexpected spikes in demand. For locally sourced materials like frames, a much shorter inventory cycle is sufficient.

Your Next Step in Planning a UAE Solar Factory

The United Arab Emirates presents a formidable platform for solar module manufacturing, combining government support with unparalleled logistical infrastructure. However, success depends on a carefully constructed global sourcing strategy.

Navigating the complexities of international procurement, quality assurance, and logistics requires specialized knowledge. The challenge is not to become an expert in all these fields overnight, but to build a plan based on proven industry practices.

Structured educational resources, such as the e-courses provided by pvknowhow.com, can offer a clear roadmap for this journey.