An entrepreneur looking to enter the solar manufacturing sector might reasonably assume a solar panel is a globally standardized product. They could source a production line from Europe or Asia, set up a factory in Dubai or Abu Dhabi, and expect performance comparable to Germany’s.

However, just six months after their high-quality panels are installed, performance reports could reveal an unexpected decline in energy yield. The culprit isn’t a fault in manufacturing, but a failure to adapt to one of the world’s most demanding environments.

The United Arab Emirates presents a unique paradox for solar energy. It boasts some of the highest solar irradiation levels globally, making it a prime location for solar power generation. Yet the very conditions that provide this abundance of sunlight—extreme heat, high humidity, and airborne sand—are the same ones that degrade standard photovoltaic (PV) modules, leading to underperformance and a shortened operational lifespan.

This article explores how standard turnkey solar production lines must be adapted for the specific climatic and market needs of the UAE to ensure long-term viability and return on investment for new manufacturing ventures.

The Challenge: A Standard Panel in an Extreme Environment

A solar panel designed for the moderate climate of Central Europe is fundamentally different from one built to withstand the rigors of the Arabian Desert. The challenges in the UAE are multifaceted:

-

Extreme Heat: Ambient temperatures can exceed 50°C (122°F). This heat, combined with direct solar radiation, can push a solar module’s operating temperature well above 80°C. High temperatures accelerate material aging and significantly reduce the electrical efficiency and energy output of standard solar cells.

-

Abrasive Sand and Dust: Fine, airborne sand, carried by winds like the Shamal, causes microscopic scratches on the surface of solar panels. Over time, this abrasion reduces the amount of light reaching the solar cells—a process known as soiling—which directly impacts energy yield.

-

High Humidity and Salinity: Coastal areas in the UAE experience high humidity, often combined with salt in the air. This corrosive atmosphere can accelerate the degradation of module components, particularly frames and electrical connections, increasing the risk of Potential Induced Degradation (PID), a phenomenon that can cause catastrophic power loss.

Simply importing a standard turnkey production line without considering these factors is a common yet costly oversight. The resulting modules might pass initial quality checks, but they won’t deliver the durability or performance expected by discerning local customers and large-scale project developers.

The Solution: Specialized Module Technology for the Region

Addressing these environmental challenges requires a specialized module design. Extensive research by institutions like the Fraunhofer Center for Silicon Photovoltaics (CSP), combined with the practical experience of engineering firms like J.v.G. Technology, has led to the development of specialized “desert-proof” modules. One such leading technology is known as DESERT+.

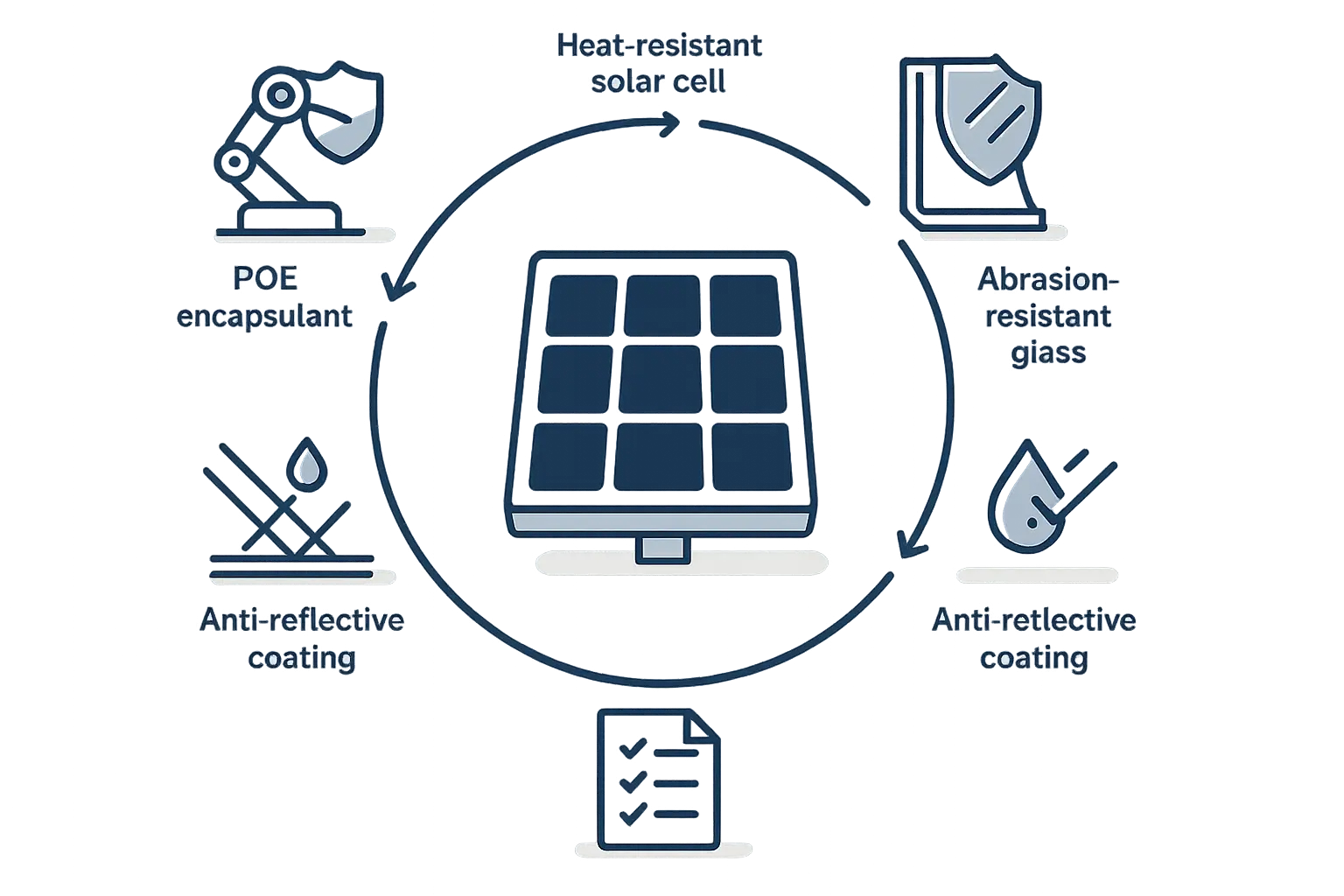

This technology isn’t a single feature but a suite of material and design modifications engineered specifically for hot and arid climates.

Key Components of a Desert-Adapted Module

-

Optimized Cell Technology: This means using cells with a better temperature coefficient, which lose less efficiency as they heat up.

-

Specialized Encapsulants and Backsheets: These modules incorporate advanced polymer materials that are highly resistant to UV radiation and can withstand extreme temperature cycles without yellowing, cracking, or delaminating.

-

PID-Free Construction: The design relies on specific materials and construction techniques that eliminate the risk of Potential Induced Degradation, a critical factor for reliability in the hot, humid conditions of the UAE.

-

Abrasion-Resistant Glass: A special anti-reflective coating applied to the front glass not only maximizes light absorption but also hardens the surface against sand abrasion.

The result is a module that maintains a higher energy yield, degrades at a much slower rate, and offers a significantly longer operational life in the UAE’s environment. For any new manufacturer, this level of specialization is a powerful market differentiator.

Adapting the Production Line for Specialized Modules

Producing a DESERT+ module requires more than different raw materials; it also demands specific adaptations to the manufacturing process itself—and this is where the concept of a standard turnkey solution needs careful reassessment.

While the core process flow of a solar factory is largely the same, several key machines within the turnkey solar production lines must be specified or modified to handle the specialized components.

-

Laminator: The laminator, which fuses the module’s layers under heat and pressure, requires precise process recipes (time, temperature, pressure) tailored to the advanced encapsulants. Using a standard recipe can lead to improper curing and premature module failure.

-

Cell Stringer: The machine that solders cells into strings must be calibrated for the specific type of solar cells chosen for their high-temperature performance.

-

Framing Station: Given the risk of corrosion, framing materials and sealing techniques often differ from standard modules, requiring adjustments at the framing station.

-

Quality Control (QC) Stations: Electroluminescence (EL) testers and “sun simulators” must be programmed with parameters that accurately reflect the performance characteristics of the desert-specific technology, not a generic module.

The factory building itself must also be designed to mitigate environmental factors. Advanced HVAC and dust filtration systems are not optional extras but essential infrastructure for ensuring a clean production environment, which is critical for module quality and longevity.

The Business Case for Specialization

For an entrepreneur exploring how to start a solar panel manufacturing business, the decision to invest in a specialized production line has clear business implications. While the initial capital outlay may be marginally higher than for a standard line, the long-term benefits create a stronger, more defensible market position.

-

Premium Product Offering: Manufacturing a certified desert-proof module lets a new entrant compete on quality and reliability, not just price. This is crucial for securing contracts for government tenders and large-scale utility projects where long-term performance is paramount.

-

Higher Bankability: Financing institutions see projects using certified, durable modules as lower risk, making it easier for customers to secure funding.

-

Enhanced Brand Reputation: A manufacturer known for producing high-performance, region-specific modules quickly builds a reputation for excellence. Experience from J.v.G. Technology’s our projects in similar climates shows that local clients highly value suppliers who understand and solve local challenges.

-

Superior Return on Investment: The higher energy yield and longer lifespan of specialized modules deliver a better ROI for the end-user, making them the logical choice for discerning buyers.

Frequently Asked Questions (FAQ)

-

What exactly is DESERT+ technology?

It isn’t a single product, but rather a certified set of specifications for materials and manufacturing processes designed to maximize a solar module’s performance and lifespan in desert environments. It was co-developed by leading research institutes and engineering firms to address challenges like high temperature, soiling, and PID. -

Can any production line be used to make these specialized modules?

Not without careful planning. While many core machines are the same, key equipment like the laminator and testing stations must be specified and calibrated for the unique materials and performance targets of desert-proof modules. An off-the-shelf line is unlikely to produce them to certified standards. -

Does a specialized production line cost significantly more?

The investment for a line capable of producing desert-proof modules is typically only moderately higher than a standard line. This added cost stems from more sophisticated machinery specifications and the use of premium raw materials. However, this investment is generally recouped through the ability to command a higher price for a superior product and access to high-value projects. -

What is the market for these modules in the GCC region?

The market is substantial and growing. Governments and large-scale developers in the UAE, Saudi Arabia, and across the Gulf Cooperation Council (GCC) are increasingly mandating higher standards for solar projects. These organizations understand that long-term reliability is key to achieving their renewable energy goals, creating strong demand for modules proven to perform in the local climate.

Conclusion: Building for Success in the UAE Solar Market

Entering the solar manufacturing industry in the UAE offers immense opportunity, but it demands a strategic approach that goes beyond standard solutions. The belief that “a panel is a panel” is a misconception that can lead to significant financial and reputational risk.

Success hinges on recognizing the region’s unique environmental challenges and investing in the right technology and production capabilities to overcome them. By adapting turnkey production lines to manufacture specialized, desert-proof modules, a new entrant can establish a powerful competitive advantage, deliver superior value to customers, and build a sustainable and profitable business in one of the world’s most promising solar markets. The journey begins not with buying equipment, but with understanding the specific problem you need to solve.