Uzbekistan has set ambitious national goals for renewable energy, aiming to install 5 GW of solar power by 2030. For savvy investors, this government-backed initiative creates a significant manufacturing opportunity. However, building a state-of-the-art solar module factory requires more than just machinery and capital; it demands a skilled, reliable, and well-trained workforce.

Many prospective investors rightly ask: Does Uzbekistan’s labor market have the necessary talent to produce solar modules that meet international standards? The answer is nuanced. While the country has a strong foundation of technical aptitude and a willing workforce, success hinges on a deliberate strategy for recruitment and, most critically, specialized in-house training. This article outlines a practical framework for building a capable factory team in Uzbekistan.

The Uzbek Labor Landscape: A Foundation of Potential

Developing an effective human resources strategy begins with understanding the local context. Several key factors shape the Uzbek labor market, creating both opportunities and challenges for a new solar enterprise.

A Young and Growing Population

Uzbekistan benefits from a significant demographic dividend. With over 60% of its 35 million people under the age of 30, the country has a large and expanding pool of potential workers. This youthful population is generally eager to learn new skills and adapt to modern manufacturing environments, representing a strong base for building a long-term workforce.

Legacy of Technical Education

The nation’s educational system, with its roots in the Soviet era, has historically emphasized technical and engineering disciplines. Universities such as Tashkent State Technical University continue to produce graduates with solid theoretical foundations in engineering, physics, and materials science. While these graduates may lack specific experience in photovoltaics, they possess the core competencies to become highly skilled technicians and engineers with proper training.

Government Focus on Vocational Skills

Recognizing the need to align education with industry demands, the Uzbek government has been actively promoting vocational training and modernizing its educational programs. This national focus creates a favorable environment for industrial investors, signaling a commitment to developing a workforce equipped for the jobs of the future. A well-structured solar factory business plan should incorporate collaboration with these local technical colleges.

Sourcing and Recruitment: A Targeted Approach

Finding the right personnel requires looking beyond traditional job postings. A multi-channel recruitment strategy is the most effective way to identify candidates with the right aptitude and attitude.

Key Roles to Recruit

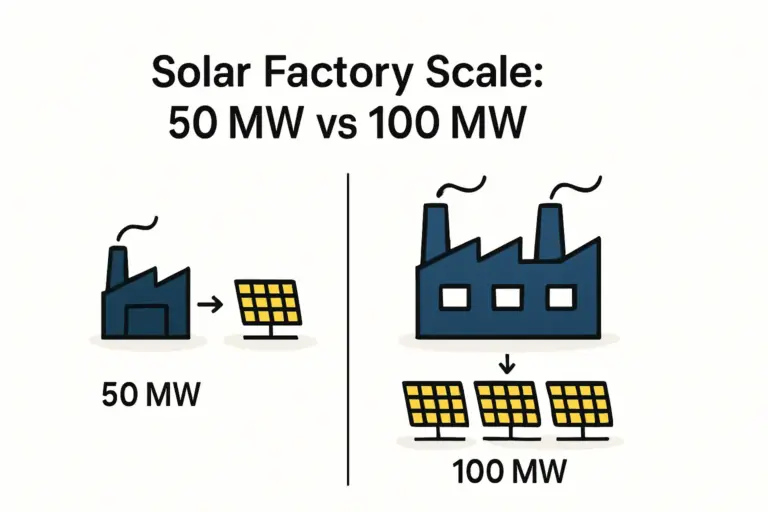

For a typical 50 MW solar module factory, an initial workforce of 25-30 employees per shift is a common starting point. The core team structure includes:

- Production Manager: Oversees all factory operations, scheduling, and output.

- Quality Control (QC) Engineers: Responsible for implementing and monitoring quality standards at every stage of production.

- Machine Operators: Trained personnel for specific equipment like stringers, laminators, and testers.

- Maintenance Technicians: Skilled staff with electrical and mechanical expertise to ensure machinery operates at peak efficiency.

- Logistics and Warehouse Staff: Manages the intake of raw materials and the storage of finished modules.

Effective Recruitment Channels

- University Partnerships: Establishing relationships with the engineering and technical faculties of local universities can create a direct pipeline of promising graduates.

- Online Job Portals: Local platforms are essential for reaching a broad audience of active job seekers.

- Technical and Vocational Schools: These institutions are an excellent source for hands-on technicians and operators who possess practical mechanical and electrical skills.

Based on recent market data, an investor can expect monthly salary ranges (gross) for key technical positions. For example, a skilled technician or engineer might command a salary between $500 and $1,200 USD, depending on experience and qualifications. These figures are competitive enough to attract capable local talent.

Bridging the Skills Gap: The Imperative of In-House Training

Finding a large pool of workers with prior experience in solar module manufacturing is unrealistic in Uzbekistan. Therefore, the most critical investment an entrepreneur will make is not in the machinery, but in the comprehensive training program for the people who operate it.

A world-class production facility is only as good as the people who run it. Based on experience from J.v.G. Technology GmbH in establishing turnkey projects globally, a structured training regimen is the single most important factor for success.

Elements of a Successful Training Program

A robust training curriculum must go beyond basic machine operation. It should be designed to instill a deep understanding of process control and quality assurance.

- Phase 1: Theoretical Foundations: Classroom sessions covering the fundamentals of photovoltaic science, materials, and the entire module production process from cell inspection to final testing.

- Phase 2: Hands-On Machine Training: Supervised, practical training on each piece of equipment in the turnkey solar production line. This phase is led by experienced engineers, often provided by the technology supplier.

- Phase 3: Quality Control Protocols: Intensive training on inspection criteria, process monitoring, and the importance of adhering to strict solar module quality standards like those set by the IEC. Operators must understand why each step is critical to the final product’s performance and longevity.

- Phase 4: Safety and Maintenance: Comprehensive instruction on workplace safety procedures and basic preventive maintenance to minimize downtime.

This systematic approach ensures that every team member not only knows how to perform their tasks but also understands the impact of their work on the quality and reliability of the final product.

Cultural and Operational Considerations

Operating effectively in Uzbekistan requires an appreciation for the local business culture. The environment is often relationship-driven, with a hierarchical management structure. Building trust with local partners and demonstrating a long-term commitment to the community can significantly smooth business operations. While Russian is widely spoken in business, having local Uzbek-speaking staff is invaluable for effective team management and daily operations.

Frequently Asked Questions (FAQ)

What is a realistic timeline for training a new factory team?

A comprehensive training program for a core team of operators and technicians typically takes four to six weeks. This includes both theoretical instruction and extensive hands-on practice before commercial production begins.

Do I need to hire expatriate experts to run the factory?

Initially, it is highly advisable to have one or two experienced expatriate engineers on-site for the first 6-12 months. Their role is to oversee the setup, lead the initial training, and establish the operational and quality control systems. The primary goal should be to train local successors to take over these leadership roles.

How do Uzbek labor laws compare to Western standards?

Uzbekistan has a formal labor code that governs employment contracts, working hours, and termination procedures. It is essential to engage local legal counsel to ensure all employment practices are fully compliant with national regulations.

What is the typical work ethic and employee retention rate?

The Uzbek workforce is generally regarded as diligent and loyal. By offering competitive wages, a safe working environment, and opportunities for professional development, factories can achieve high employee retention rates.

Conclusion: Building a Foundation for Long-Term Success

Uzbekistan offers a compelling opportunity for establishing a solar module manufacturing facility. The country has a young, technically-inclined workforce and a supportive government policy environment. However, the path to success is not simply about acquiring technology; it is about developing people.

An entrepreneur who prioritizes a structured recruitment strategy and invests in a comprehensive, in-house training program will be well-positioned to build a highly capable team. This focus on human capital is the key to manufacturing high-quality solar modules that can compete on the international stage and contribute to Uzbekistan’s renewable energy future.