An investor reviews the plans for a new solar module factory: the machines are specified, the building layout is complete, and the supply chain for materials is mapped out. Yet, one critical question is often overlooked: Who will operate this advanced equipment to the high standards required, especially in a region where specialized industrial experience isn’t widespread?

Entrepreneurs entering the solar manufacturing sector in markets like Yemen often face this scenario. While the nation has immense solar energy potential and a large, youthful population, a gap exists between the available labor force and the specific technical skills required for precision manufacturing.

This article outlines a practical blueprint for turning this challenge into a strategic advantage. It lays out a structured approach to recruiting, training, and developing a local workforce capable of operating a modern solar module assembly plant efficiently and sustainably.

Understanding the Local Context: Challenges and Opportunities

Building a successful workforce starts with understanding the local environment. In Yemen, the business landscape is shaped by unique factors. Reports from international development agencies indicate that years of conflict have disrupted formal education and vocational training systems, resulting in a limited pool of candidates with prior experience in industrial manufacturing or quality control.

However, this challenge presents a significant opportunity. The same conditions have fostered a population known for its resilience and adaptability. There is a strong demand for stable, skilled employment, which creates a highly motivated pool of potential trainees. The urgent need for decentralized, reliable energy makes a local solar manufacturing venture not just a commercial enterprise, but a project of national importance. An investment in local talent is an investment in the country’s energy independence.

The Foundation: Why a Specialized Training Program is Non-Negotiable

In solar module assembly, precision is paramount. A single misaligned cell, an improperly soldered ribbon, or a microscopic crack invisible to the naked eye can compromise the performance and longevity of the final product. Simply hiring general laborers and expecting them to learn on the job is a high-risk strategy that often leads to low yields, high material wastage, and significant operational delays.

A structured, in-house training program is the most reliable way to mitigate these risks. This essential upfront investment pays dividends through:

- Standardized Quality: Ensuring every operator understands and adheres to the same high standards.

- Reduced Defect Rates: Proper training minimizes common errors, saving costs on materials and rework.

- Operational Efficiency: A well-trained team can run production lines at their optimal capacity.

- Workplace Safety: Instilling a culture of safety from day one, protecting both staff and equipment.

This systematic approach transforms a group of individuals into a cohesive, high-performing production team.

A Four-Phase Blueprint for Workforce Development

A successful training program guides trainees from novice to proficient operator. This process can be broken down into four distinct phases, creating a clear pathway to competence. Based on experience from J.v.G. turnkey projects in emerging markets, this model has proven effective.

Phase 1: Strategic Recruitment and Selection

The goal of recruitment is not to find experienced solar technicians—they may not exist locally. Instead, the focus should be on identifying individuals with the right aptitude and attitude.

Key criteria for selection should include:

- Manual Dexterity: The ability to handle delicate components with care.

- Attention to Detail: A capacity for focused, meticulous work.

- Problem-Solving Skills: The ability to think logically when faced with minor issues.

- Willingness to Learn: A positive attitude toward acquiring new technical skills.

Screening can involve simple practical tests, such as assembling small mechanical puzzles or performing tasks that require steady hands. Collaborating with local community leaders or technical institutes can also help identify promising candidates.

Phase 2: Foundational Technical Training (The ‘Bootcamp’)

Once a cohort is selected, they enter a foundational training phase. This ‘bootcamp’ is a mix of classroom theory and basic practical exercises conducted away from the main production line. The goal is to build a common knowledge base.

Topics covered should include:

- Introduction to Solar PV: How solar cells work and why quality matters.

- Workplace Safety: Protocols for handling equipment, materials, and electricity.

- Quality Control Principles: The concept of ‘right first time’ and how to identify common defects.

- Manufacturing Overview: A high-level walk-through of the entire solar panel manufacturing process explained to provide context for each individual role.

This phase ensures that every team member, regardless of their future specialization, shares a common technical language and understands their contribution to the final product.

Phase 3: Hands-On Specialization

With the foundation in place, trainees move to the production floor for hands-on, role-specific training. This is best done in small groups under the direct supervision of an experienced trainer, who could be an external expert or a future team lead.

Training is structured station by station, focusing on the equipment of the turnkey solar panel production line. For a semi-automated line, key training modules would include:

- Cell Stringing: Operating the stringer machine to connect solar cells with precision.

- Layup/Bussing: Assembling the ‘sandwich’ of glass, EVA, cells, and backsheet.

- Lamination: Operating the laminator, a critical step that requires understanding time, temperature, and pressure parameters.

- Framing and Junction Box Installation: Finishing the module to ensure its structural integrity and electrical connectivity.

- Testing: Using EL testers to spot microcracks and IV testers (sun simulators) to verify performance output.

Each trainee masters one station before moving to the next, with proficiency measured against clear quality and time benchmarks.

Phase 4: Integration and Continuous Improvement

Graduating from specialized training doesn’t mark the end of development. The final phase focuses on integrating new operators into the full production team and fostering a culture of continuous improvement.

Key elements include:

- Mentorship: Pairing new operators with a senior team member or shift leader for ongoing guidance.

- Performance Monitoring: Tracking key metrics like individual output and defect rates to provide constructive feedback.

- Cross-Training: Once an operator is proficient in their primary role, training them on adjacent stations builds a more flexible and resilient workforce.

This phase ensures that skills are retained, refined, and shared throughout the organization.

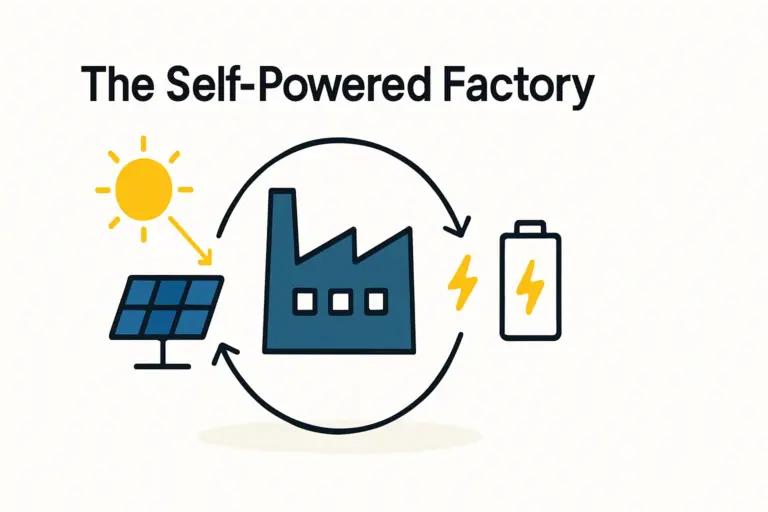

The Outcome: A Self-Sustaining, High-Performing Team

The result is not just a group of trained individuals, but a local, self-sustaining, and highly capable operational team. This team becomes a core asset of the business, ensuring consistent production quality, operational stability, and a strong sense of local ownership.

This strategic investment in people reduces long-term reliance on external experts, lowers staff turnover, and builds a powerful local reputation. A well-trained team is the engine that drives a solar factory from a startup venture to a profitable, long-term operation.

Frequently Asked Questions (FAQ)

What is the ideal background for a trainee?

An ideal candidate doesn’t necessarily need a technical diploma. Qualities like good hand-eye coordination, a patient and detail-oriented nature, and a strong work ethic are more important. A background in crafts, electronics repair, or other fields requiring fine motor skills can be advantageous.

How long does the full training program take?

The initial intensive training (Phases 2 and 3) typically takes between four to eight weeks, depending on the complexity of the production line. Reaching full productivity and proficiency (Phase 4) can take an additional three to six months of on-the-job experience and mentorship.

Do we need to hire trainers from abroad?

Initially, it’s highly recommended to bring in one or two experienced trainers, often supplied by the equipment provider like J.v.G. Technology. Their primary role is twofold: to train the first cohort of operators and, crucially, to ‘train the trainers’ by identifying and developing local talent to become future shift leaders and instructors.

What is the typical team size for a small-scale factory?

For a semi-automated factory with an annual capacity of 20–50 MW, a production team of 20–30 operators and technicians per shift is a common benchmark. This includes roles across the entire assembly line, plus quality control and material handling.

Conclusion: From Labor Potential to Operational Excellence

The perceived skills gap in a market like Yemen is not an insurmountable barrier to establishing a high-tech manufacturing facility. It’s a manageable challenge that, when addressed with a structured training program, becomes a source of competitive advantage.

By investing in local talent, an entrepreneur not only secures the factory’s operational success but also contributes directly to the region’s economic development and energy resilience. The process begins with recognizing that the most valuable components of a solar factory are not the machines, but the skilled people who operate them.

For entrepreneurs considering this venture, understanding the complete project scope is crucial. A detailed guide on how to start a solar module factory provides a comprehensive overview of all necessary steps.