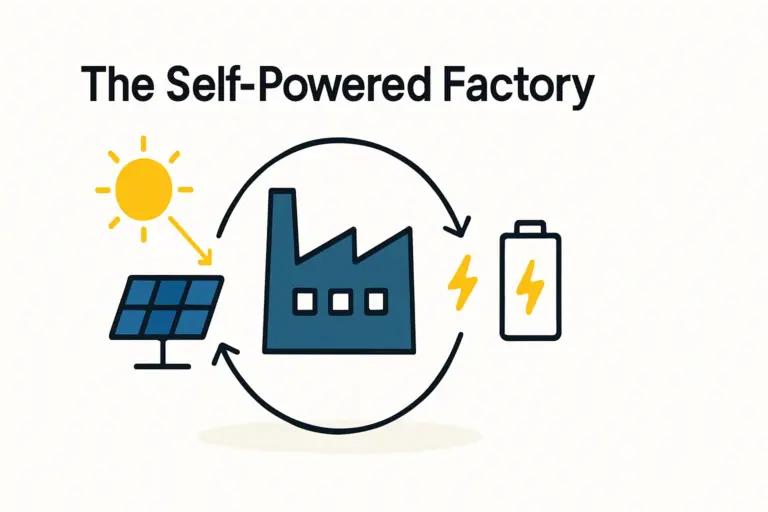

Yemen has one of the highest solar irradiation levels in the world, with over 2,200 kilowatt-hours per square meter annually. Yet, the nation faces a profound energy crisis following the collapse of its national grid.

This challenging situation has created a unique and rapidly growing market for solar power, driven almost entirely by necessity. For entrepreneurs considering entry into solar module manufacturing, Yemen presents a compelling, albeit complex, opportunity.

Success in this market requires more than just importing standard, mass-produced solar panels. The specific conditions in Yemen demand a thoughtful approach to module technology—one that prioritizes durability and reliability over headline efficiency figures. This guide analyzes the optimal module specifications for Yemeni end-users and outlines the strategic advantages for local manufacturers.

Understanding the Yemeni Solar Landscape

The solar market in Yemen is fundamentally different from those in developed nations. It isn’t driven by grid-feed-in tariffs or large-scale utility projects. Instead, it is shaped by the following realities:

-

Dominance of Off-Grid Systems: An estimated 95% of the market consists of small-scale, off-grid residential and commercial systems. Families and small businesses are purchasing solar solutions for basic needs like lighting, water pumping, and powering essential appliances.

-

Price Sensitivity and Quality Awareness: While end-users are highly price-sensitive, many have experienced the consequences of low-quality imports. There is a growing demand for products that are durable and long-lasting, as repeat purchases represent a significant financial burden.

-

Lack of Regulation: The absence of strong standards and enforcement has led to a flood of low-grade modules, often with falsified specifications. This has created deep-seated distrust among consumers, but it also presents an opportunity for a reputable local producer to build a brand on trust.

These factors make it clear that the most significant market gap isn’t for the cheapest or most efficient panel, but for the most reliable and well-engineered one.

Key Technical Challenges and Solutions

A solar module designed for a European rooftop will not perform optimally over its lifetime in Yemen. Local manufacturers must engineer their products to withstand a unique set of environmental stressors.

The Impact of Dust and High Temperatures

The primary environmental challenges are extreme heat, dust, and frequent sandstorms. These conditions directly affect a module’s performance and lifespan.

-

Soiling Losses: Dust accumulation on the module surface can significantly reduce energy output.

-

Abrasive Damage: Over time, wind-blown sand can cause micro-scratches on the glass surface, diminishing its transparency.

-

Heat Degradation: High ambient temperatures accelerate the aging of module components, particularly the backsheet and encapsulants, leading to premature failure.

To address these issues, manufacturers should focus on robust construction. The goal is to build a module that maintains its integrity and performance for decades, not just a few years.

Module Construction: Prioritizing Durability

The choice of materials is critical. While many imported panels use a standard glass-backsheet design to reduce costs, a more resilient construction offers a distinct advantage in Yemen’s climate.

Glass-Glass (GG) vs. Glass-Backsheet (GB):

A glass-glass module, which sandwiches the solar cells between two layers of glass, offers superior protection against environmental factors.

-

Mechanical Stability: The dual-glass structure provides enhanced rigidity, making the cells less susceptible to microcracks caused by handling or wind loads.

-

Moisture and Heat Resistance: Glass is an impermeable barrier to moisture and is far more resistant to degradation from UV radiation and heat than a polymer backsheet. This is crucial for preventing delamination and cell corrosion over the long term.

-

Durability: A glass-glass module is simply a more robust product, better suited to withstand the harsh conditions prevalent across the region.

While glass-glass construction has a slightly higher initial material cost, its extended lifespan and reliability create a powerful value proposition for the end-user.

Cell Technology and Module Size

The market currently shows a preference for monocrystalline PERC modules, which offer a good balance of efficiency and cost. Manufacturers don’t need to pursue the latest, most expensive cell technologies (like TOPCon or HJT) for this market segment. Proven, reliable technology, such as 5 busbar (5BB) PERC cells, is often sufficient and more cost-effective for popular module sizes.

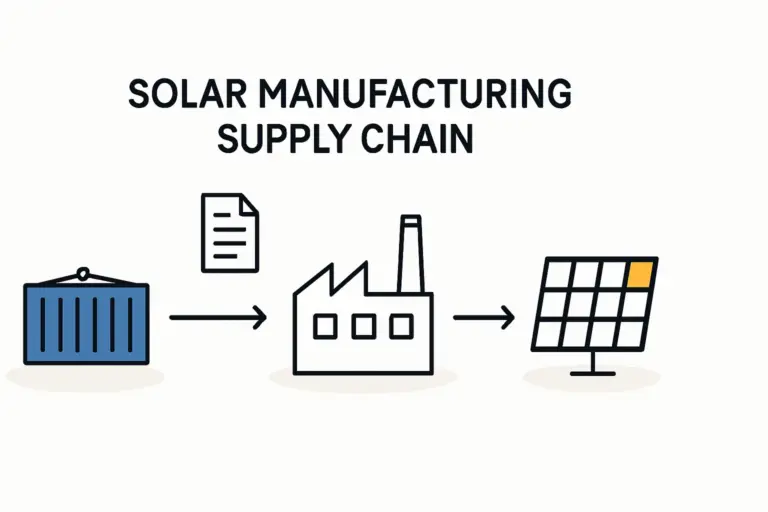

Demand is concentrated in two main categories:

-

Small Modules (100-180 Wp): Used for basic lighting and small appliance systems.

-

Larger Modules (300-550 Wp): Used for more substantial residential or small commercial applications, such as powering water pumps or workshops.

A local manufacturer can gain a strategic advantage by reliably producing these specific sizes, ensuring consistent quality where importers often fail.

The Strategic Advantage of Local Manufacturing

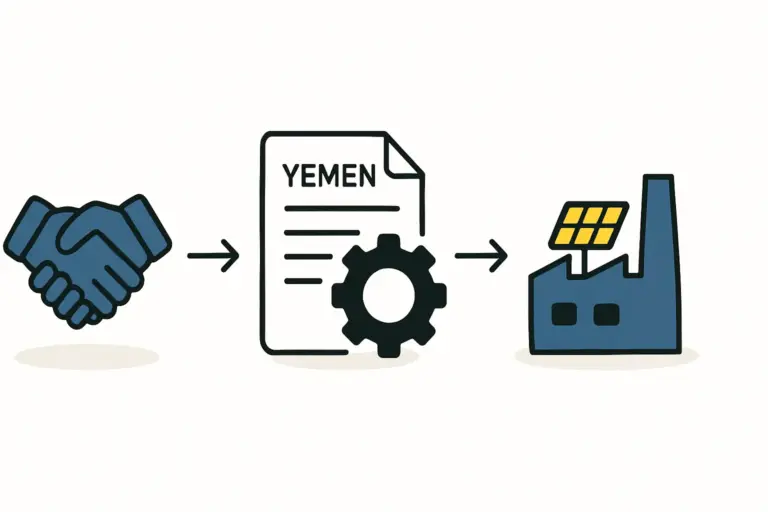

Competing on price alone against large-scale international producers is an uphill battle. The opportunity in Yemen lies in building a brand based on trust, quality, and local presence.

A local factory can:

-

Control Quality: Directly oversee the entire production process, from incoming materials to final testing. This makes it possible to build a module genuinely designed for the local environment. A comprehensive solar module manufacturing machine list is the foundation for this quality control.

-

Build Trust: A physical presence, transparent processes, and tangible products create a level of confidence that anonymous importers cannot match. This trust can be further solidified by obtaining internationally recognized solar module certification.

-

Offer Local Support: Providing after-sales service and technical support is a powerful differentiator that addresses a key pain point for consumers let down by low-quality imports.

-

Tailor Products: Produce the exact module types and sizes the local market demands, adapting more quickly to changing needs than a distant, large-scale manufacturer.

Based on experience from J.v.G. Technology GmbH turnkey projects in similar emerging markets, a local brand that delivers on its promise of durability can command a price premium and secure a loyal customer base.

Frequently Asked Questions (FAQ)

Q1: Is it truly possible for a local factory to compete with low-cost Chinese imports?

Yes, but not by competing on price alone. The competitive edge comes from offering a verifiably higher-quality product tailored to local conditions, backed by local service and a trustworthy brand. End-users who have experienced premature failures with cheap imports are often willing to pay more for reliability.

Q2: Why not just use the highest-efficiency modules available?

For an off-grid user in Yemen, the total energy produced over a 25-year lifespan matters more than a marginal gain in peak efficiency. A durable module that resists degradation will deliver more value over time than a high-efficiency module that fails after five years due to heat and humidity. The business case favors longevity.

Q3: What are the first steps to exploring this manufacturing opportunity?

The first step is a thorough feasibility study and planning phase. This involves understanding the full scope of how to start a solar factory, from building requirements to logistics. A detailed solar business plan is essential to secure financing and guide the project. The educational resources available at pvknowhow.com provide a structured framework for this process.

Q4: What specific module features should a local manufacturer prioritize?

Beyond glass-glass construction, priorities should include a robust, anodized aluminum frame to resist corrosion, a high-quality, weatherproof junction box with reliable bypass diodes, and strong quality control during the lamination process to prevent defects.

Engineering for Resilience

The solar market in Yemen is a direct response to a critical human need. For an entrepreneur, it represents an opportunity to build a meaningful and profitable enterprise by delivering a product that solves a real problem.

Success hinges on a strategic shift in thinking: away from the global obsession with peak efficiency and toward a focused commitment to resilience and long-term value. By engineering a module specifically for Yemen’s challenging environment, a local manufacturer can not only meet a pressing market demand but also build a lasting reputation for quality and trust.