Solar is a fast-growing industry. In 2021, power generation from solar PV increased by a record 179 TWh, a 22% jump from 2020 production.

Solar PV accounts for 3.6% of global electricity generation, a significant figure considering that solar energy is still relatively new to the global energy mix.

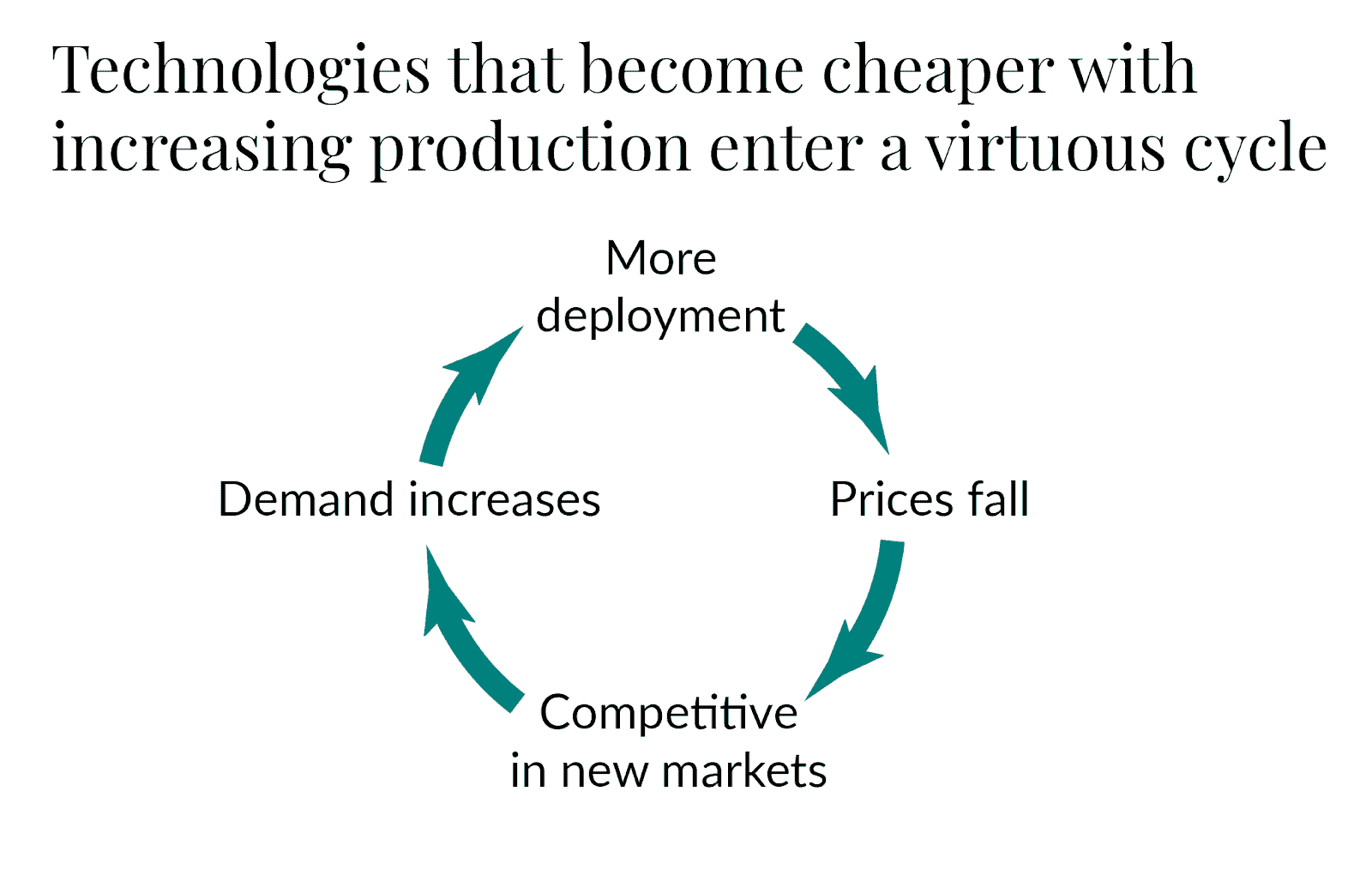

This growth rate shows how solar is becoming increasingly cost-competitive with other energy sources, making it a viable option for individuals, utilities, businesses, and investors.

As the demand for solar energy continues to rise, so does the need to manufacture solar panels. Investing in solar panel manufacturing is a lucrative business, with the potential to generate high returns.

The size of the returns or the ROI is mostly influenced by the scale of the project. The larger the project, the riskier it will be. But where there are greater risks, there are greater rewards.

Scaling a solar manufacturing business means taking on bigger risks and overcoming certain challenges. Some of the biggest challenges include capital costs, access to financing, lack of uniformity in regulations, and policies when operating in different markets.

This article takes an in-depth look at the challenges of scaling production and then at a few strategies you can implement to overcome these challenges.

Challenges of Scaling Solar Module Production

It’s not uncommon for a business owner to start small - for example with a 10MW production line - and then expand production later. However, there are a few challenges to scaling production.

Limited Access to Financing

Access to financing is one of the major challenges of scaling solar panel manufacturing. It’s difficult for small-scale manufacturers to secure the necessary financing to expand production capacity. Banks and other financial institutions can be hesitant to lend money to small-scale manufacturers due to the perceived risks.

High Interest Rates for Financing

Even if a small-scale manufacturer is able to secure financing, they are often faced with high interest rates. This can significantly increase the cost of production, which can make it difficult to compete with larger manufacturers who have access to cheaper financing.

The Complexity of Supply Chain

Solar manufacturing involves a complex supply chain, which can present additional challenges when scaling production. From sourcing raw materials to managing production, the supply chain must be managed effectively to ensure a smooth and efficient production process.

The complexity of the supply chain makes it critical for manufacturers to have access to reliable suppliers, especially when they step up their demand. This can be difficult if existing suppliers cannot meet the demand.

Fluctuations in Demand

Demand for solar has been on a fairly consistent growth curve, but it can fluctuate depending on the market, changes in policies, or other unforeseen factors.

When investing in solar manufacturing, it is important to consider the challenges of scaling production to meet demand. This involves forecasting future demand and ensuring that production capacity is sufficient to meet it.

This can be difficult because forecasting demand is not always accurate and can result in either overproduction or underproduction.

The influence of demand on prices. Image Source: Max Roser

Lack of Uniform Regulations and Policies Across Markets

Different countries and regions have different regulations and policies regarding solar energy production, which can complicate plans to expand operations and scale production.

This can create additional challenges for manufacturers, as they must be aware of and take into consideration the regulations and policies that apply to the markets they are looking to expand into.

Increasing Competition

The solar energy industry is becoming increasingly competitive. Large-scale manufacturers have access to more resources and can often produce solar panels at a lower cost than smaller manufacturers. This can create a barrier for small-scale manufacturers, making it difficult for them to scale production and remain competitive.

Risk of Disruption Due to China's Control of Solar Manufacturing

China has become the dominant force in solar manufacturing, controlling more than 80% of the global market share. This has caused concerns about the security of the global solar supply chain, as China’s control of the market could potentially lead to supply disruptions or even price manipulation.

Price manipulation would make it difficult for small solar manufacturers to compete and could even price them out of the market.

Guidelines for Scaling Solar Production

We have looked at some of the obstacles that might make it difficult to grow a PV manufacturing business. Below are some guidelines that can help you successfully navigate some of those obstacles.

Research the Market

Every successful venture starts with researching the market to gain a better understanding of the industry. This involves researching the regulations and policies that apply to the industry, examining market trends, and understanding the competitive landscape.

This will allow investors to gain a better understanding of the industry and identify potential opportunities for growth. Research is essential to developing product-market fit, demand, competitive advantage, and several other factors that can help a business to thrive.

Develop a Clear Business Plan

A clear and well-defined business plan is essential for growing any business. A business plan for solar production should include a detailed plan for how the business will achieve its goals, including the target market, product offering, pricing, marketing strategies, and more.

It should also include financial projections, such as estimated revenue and capital requirements. A business plan acts as a roadmap, providing guidance and a plan of action for the business.

Secure Cheap Financing

Understanding the market and market trends is vital to scaling up operations. But very often financing is usually the biggest obstacle to growing a solar manufacturing business.

Investors should ensure that they have access to the necessary financing to scale production and improve operations.

This can involve securing loans from banks and other financial institutions or seeking investments from venture capitalists and other investors. Financing can also be obtained from government grants. Here is a complete guide on where to get financing for solar module manufacturing.

Cheap financing will allow a PV panel manufacturing business to grow while maintaining its competitiveness.

Find Reliable Suppliers of Raw Materials

The supply chain is a crucial aspect of solar module manufacturing. A shock or uncertainty around the supply chain can affect production or hurt investor confidence and increase the cost of financing.

This is why it is important for investors to find reliable suppliers of raw materials. This involves researching potential suppliers, establishing partnerships, and negotiating contracts. Having reliable suppliers of raw materials will ensure that production is not interrupted, quality control is maintained, and investor sentiment is high.

It is also important to forge strategic partnerships that can help you develop an efficient distribution network that ensures solar panels are delivered quickly and without damage. An effective distribution network should include a well-planned route for delivery, reliable transport, and an efficient system for tracking inventory and orders.

Investing in the Latest Technology

Machinery and technology play a big part in the operation of a solar manufacturing plant. It is important to invest in the latest technology. This involves investing in the latest equipment, software, and other technologies that can improve efficiency and reduce costs. This will allow investors to remain competitive in the industry and maximize their profits.

Build Long-Term Relationships

Good relationships are the cornerstone of a profitable business. Building strong long-term relationships with suppliers, partners, and customers is important for staying competitive in a growing industry.

Focus on providing excellent customer service and developing mutually beneficial relationships with suppliers and partners. Offer incentives and reward loyalty. This will help to build trust and grow your business.

Marketing

A final point to consider is the importance of marketing in growing a PV manufacturing business. Very often this is a neglected part of most businesses. Invest in traditional and modern marketing methods.

Traditional marketing for a solar module manufacturer includes trade shows, events, and business networking. Modern marketing consists mostly of digital marketing which is the use of online platforms to promote products and services.

This includes content marketing, social media marketing, email marketing, search engine optimization, and more. Leveraging digital marketing will help to reach potential customers, build brand awareness, and engage with existing customers.

Digital marketing will also help to increase sales and revenue, as well as provide valuable customer data and insights that would be hard to obtain using traditional marketing methods.

Here is a complete guide on marketing strategies for solar manufacturers.