Solar Panel Frame and Solar Framing Machine

A solar panel frame is a frame made of aluminum that seals and secures the parts of a solar panel, like the solar cells and glass. It is like the main part of PV solar panels. It is really important in putting together a solar panel.

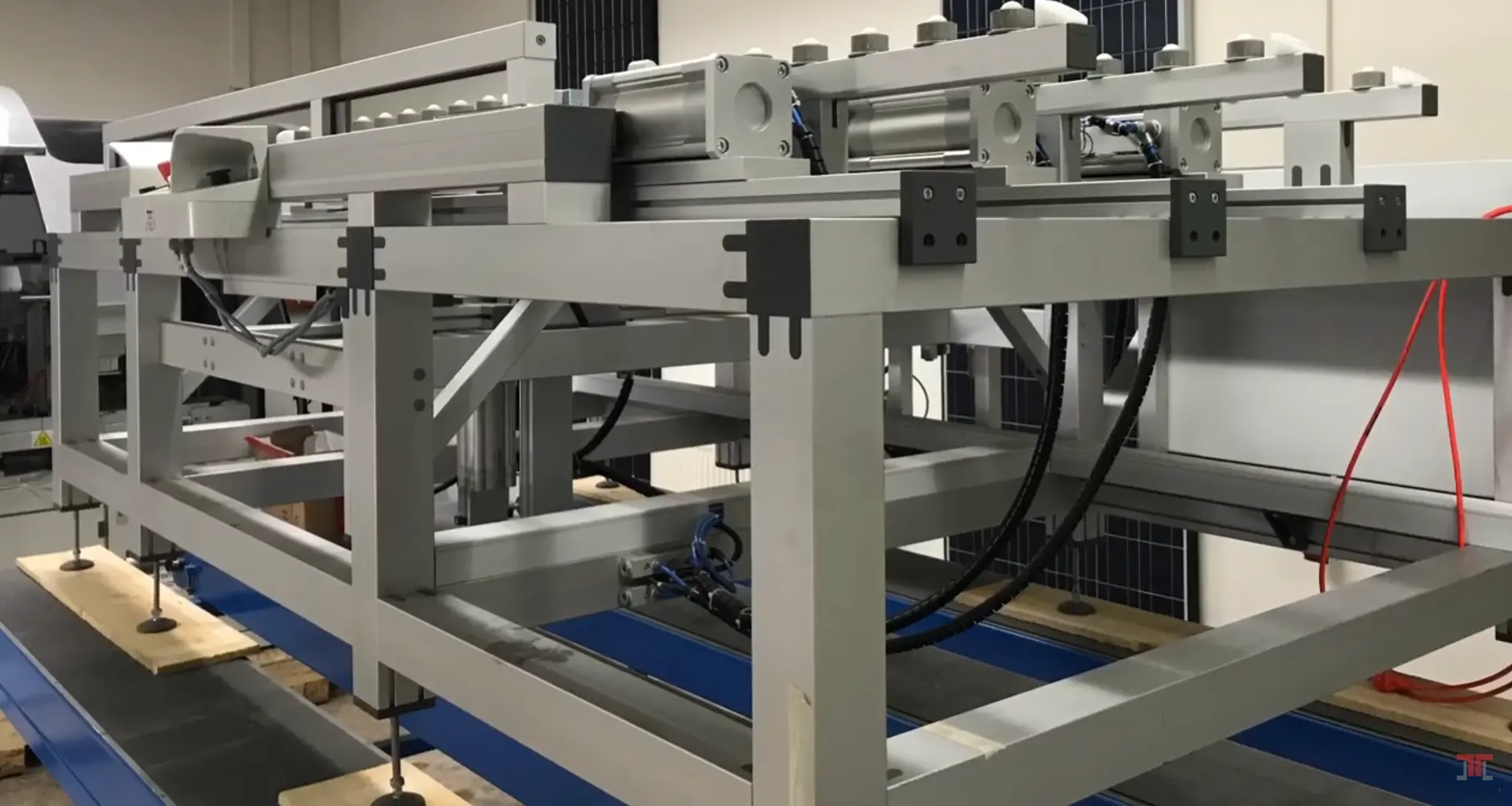

A machine called a solar panel framing machine is used in the process of making solar panels. It helps to position and secure the solar cells, back sheets, and other parts inside an aluminum frame.

We will learn about the structures and components of machines used for making solar panels. We will find out what materials they are made from, how they function, and why they are essential for producing solar panels effectively.

Full Auto Solar Panel Frame Machine

Solar Panel Frame Materials

The most common material used for solar panel frames is aluminum, specifically aluminum alloys from the 6000 series, like 6063 and 6005. Here are the main things to know about the materials used in solar panel frames:

- Aluminum alloys: Aluminum alloys 6063 and 6005 are the primary materials used for solar panel frames due to their high strength, firmness, and corrosion resistance .

- Anodized aluminum: High-quality solar panels often feature anodized aluminum frames, which offer improved heat reflection, easy maintenance, and scratch resistance compared to powder-coated alternatives .

- Powder-coated aluminum: Powder-coated aluminum frames are preferred for their aesthetic appeal, as they come in various colors (mostly black) and finishes (gloss, matte, or satin). However, they are more prone to scratches than anodized frames .

- Mechanical properties: Aluminum alloys used in solar panel frames have high tensile strength, yield strength, elasticity, rigidity, and metal fatigue value .

- Chemical composition: The aluminum alloys used contain small amounts of silicon, iron, copper, manganese, magnesium, chromium, zinc, and titanium, with aluminum being the primary component .

- Durability: Aluminum frames have a service life of more than 25 years and can adapt to various environments

Key Components of Solar Panel Framing Machines

Solar panel framing machines are complicated systems that use different special parts to do the job of making the frames. If we know what these parts are, we can understand how important and precise these machines are in making solar panels. Let's look at the main parts that help these machines work well.

Frame Handling and Preparation System

The frame handling and preparation system is responsible for loading, positioning, and securing the solar panel frame in the correct orientation for the assembly process.

- Frame feeding mechanisms: Automated or semi-automated systems that load the empty frames into the machine.

- Frame positioning and clamping: Devices that precisely align and hold the frame in place during the assembly steps.

- Frame cleaning and preparation: Stations that clean, inspect, and prepare the frame for the component integration process.

Component Positioning and Alignment Systems

Precise positioning and alignment of the solar cells, back sheets, and other components within the frame are critical for optimal performance and durability.

- Vision systems: Camera-based systems that use computer vision algorithms to detect and align the various components.

- Laser guidance: Laser-based alignment mechanisms that precisely position the components within the frame.

- Mechanical alignment: Mechanical devices, such as guides, stops, and positioners, that physically align the components.

Securement and Bonding Mechanisms

Once the components are positioned within the frame, the framing machine must securely hold them in place.

- Adhesive application: Automated systems that dispense adhesives, such as silicone sealants or epoxy, to bond the components to the frame.

- Mechanical clamping: Devices that apply mechanical force to hold the components firmly in place within the frame.

- Welding or soldering: Specialized welding or soldering processes that create a permanent, secure bond between the components and the frame.

Quality Inspection and Monitoring Systems

Maintaining high product quality and identifying potential defects is crucial in the solar panel manufacturing process.

- Vision-based inspection: Camera systems that capture images of the assembled panel and use computer vision algorithms to detect misalignments, incomplete bonding, or other defects.

- Sensor-based monitoring: Strategically placed sensors that continuously monitor parameters such as component positioning, adhesive application, or weld quality.

- Data logging and analysis: Software systems that record and analyze production data to identify trends, optimize processes, and facilitate continuous improvement.

Automation and Control Systems

Modern solar panel framing machines rely on advanced automation and control systems to ensure seamless operation and efficient production.

- Programmable Logic Controllers (PLCs): Computerized control systems that manage the various processes and sequences within the framing machine.

- Human-Machine Interfaces (HMIs): Interactive displays that allow operators to monitor, control, and troubleshoot the machine's operations.

- Networking and communication: Connectivity features that enable remote monitoring, data exchange, and integration with broader production management systems.

Material Handling and Integration

Solar panel framing machines must be integrated into the overall solar panel production line, seamlessly interfacing with upstream and downstream processes.

- Automated conveyor systems: Belts or rollers that transport the frames and components through the various stages of the framing process.

- Robotic arms: Programmable robotic manipulators that handle and transfer the frames and components between stations.

- Integrated process control: Coordination systems that synchronize the framing machine's activities with the broader production workflow.

Process of Building A Solar Panel Frame

solar panel framing process, carried out by specialized framing machines, is a vital step that provides structural support, protection, and mounting functionality to solar panels.

The Solar Panel Frame Building Process Typically Involves The Following Steps:

- Prepare and debug the aluminum frame according to the size of the solar panel components.

- Install the aluminum frame on the spreading machine for automatic gluing.

- Place the solar cell strings or glass on the frame, ensuring proper alignment. The glass should be facing downwards.

- Activate the framing machine. Cylinders on both sides will automatically squeeze and clamp the frame onto the glass.

- The operator checks the alignment of the glass edge with the frame. The side angle should be 90 degrees.

- Manipulate the button, cylinder, head restriction, and other controls to complete the clamping process.

- Remove the framed panel and inspect for proper alignment, fragments, bubbles, and any defects.

- Allow the framed panel to solidify for 10-12 hours.

- Clean the module to remove dust, foreign objects, or spilled sealant.

Key Points About Building A Solar Panel Frame:

- Framing machines automate and optimize the process, ensuring precision, consistency, and efficiency.

- The machines integrate with upstream processes like cell manufacturing and downstream processes like lamination.

- Proper framing is crucial for the panel's structural integrity, protection from the elements, and mounting capabilities.

- Quality control checks are performed to identify any misalignments, incomplete bonding, or defects.

- The framing process directly impacts the panel's performance, durability, and overall quality.

Importance of Solar Panel Framing

The process of framing solar panels is very important in making them. It affects how well they work, how long they last, and how easy it is to sell them. Mistakes or problems in the framing can make the solar panels less powerful, produce less energy, and not last as long. This can make it harder for people to make money from them. That's why we use machines to help with the framing process. These machines make sure that the solar panels are made correctly every time, so they work well and last a long time.

Here are the key points highlighting the importance of solar panel framing:

Structural Support

The frame gives a strong and lasting structure to hold up the sensitive solar cells, back sheets, and other parts, keeping them safe from harm and making sure the solar panel will work well for a long time.

Mounting and Installation

The frame makes it easy to safely put the solar panel on different surfaces like roofs, on the ground, or on tracking systems.

Aesthetics and Appearance

The frame makes the solar panel look nicer and helps it blend in with its surroundings.

Electrical Connectivity

The frame might have things that make it easy to connect electricity, like junction boxes or wiring harnesses.

Solar panel framing machine

The Role of Solar Panel Framing Machines in the Production Workflow

Solar panel framing machines are very important in the process of making solar panels. They help connect different parts of the production process together.

The machine that makes the frames for solar panels needs to work well with the other machines before and after it. This will help make sure the panels are finished smoothly and without any delays in the whole production process.

By knowing how solar panel framing machines work in the bigger picture of manufacturing, companies can make their production better, make their work smoother, and make sure they always have good solar panels to sell.

Factors Influencing the Efficiency and Effectiveness of Solar Panel Framing Machines

Many important things can affect how well solar panel framing machines work and how good the solar panels they make are. Let's look at these important factors:

1. Production Capacity and Throughput

The framing machine needs to match the production goals and volumes of the solar panel factory. Choosing a machine with the right speed, cycle time, and output can help avoid problems, make things run smoothly, and reach production targets.

2. Automation and Precision

The level of automation and how accurate the framing machine's parts are positioned and aligned are very important to make sure the products are of good quality and don't have many mistakes. Using advanced technology like automation, computer vision, and robots can make the framing process more precise and consistent.

3. Flexibility and Adaptability

As the solar panel industry keeps changing and improving, it's important for the framing machine to be able to adapt to these changes. Machines that are flexible and modular can work with different panel sizes and designs, helping manufacturers to stay competitive and meet the demands of the market.

4. Integration and Connectivity

Seamless integration of the framing machine with the broader production line, as well as its connectivity to data management and control systems, can significantly enhance operational efficiency. Features like automated material handling, process synchronization, and remote monitoring and control can optimize workflow, minimize downtime, and facilitate data-driven decision-making.

5. Maintenance and Serviceability

Ensuring the long-term reliability and availability of the framing machine is crucial for sustained production. Design features that prioritize ease of maintenance, accessibility for servicing, and the availability of spare parts can minimize downtime and enable proactive maintenance strategies.

6. Energy Efficiency and Environmental Impact

As the solar industry strives for environmental sustainability, the energy efficiency and environmental impact of the framing machine are becoming increasingly important considerations. Manufacturers should prioritize machines with energy-efficient designs, reduced waste generation, and the utilization of eco-friendly materials and processes.

7. Operator Ergonomics and Safety

The health and safety of the workers who operate the solar panel framing machines are really important. Having features that make it easier to use, interfaces that are easy to understand, and safety systems that are strong can make the work environment better, help people work better, and reduce the chance of accidents at work.

8. Total Cost of Ownership

When choosing machines to make solar panels, companies need to think about how much it will cost overall. This includes how much money they need to spend at the beginning, how much it costs to run the machine, how much maintenance it needs, and how much money they'll make in the long run. By looking closely at these things, they can pick the best option for their production needs.

Solar panel framing machines are really important in making solar panels. They help put the panels together and make sure they are strong and work well. These machines are specialized to make sure the panels are high quality and work properly.

By learning about how solar panel frames and machines work, including what parts they have, how they are put together, and what things affect how well they work, companies can make smart choices when buying these important tools for making solar panels.