Kaneka Corporation has initiated pilot-scale production of organic photovoltaic (OPV) modules at its Takasago Plant in Hyogo Prefecture, Japan, starting in January 2025. This strategic move marks a critical step in the company’s mission to develop and commercialize next-generation solar technology, with an initial focus on applications in consumer electronics.

Advancing Technology for Organic solar modules

Organic solar cells represent a promising alternative to traditional silicon-based solar panels. Often called OPV, these cells are remarkably lightweight, flexible, and are produced using carbon-based [solar panel raw materials]. This unique composition allows for innovative applications on curved surfaces, windows, or facades where conventional rigid panels are impractical. For homeowners and tenants in Germany, this could mean future solar solutions for historically protected buildings or rental properties with strict structural limitations.

Despite their vast potential, organic solar cells have historically faced challenges in conversion efficiency and long-term durability. Kaneka is directly tackling these hurdles. The company has already achieved a world-record conversion efficiency of 16.3% for a module measuring 80 cm x 30 cm. Looking ahead, Kaneka plans to boost performance further by creating hybrid cells that combine organic semiconductors with highly efficient perovskite materials. A key focus is also on enhancing the durability of these modules, with the ambitious goal of achieving a lifespan of over 20 years.

The Role of the Takasago Plant in Organic solar modules Pilot Production

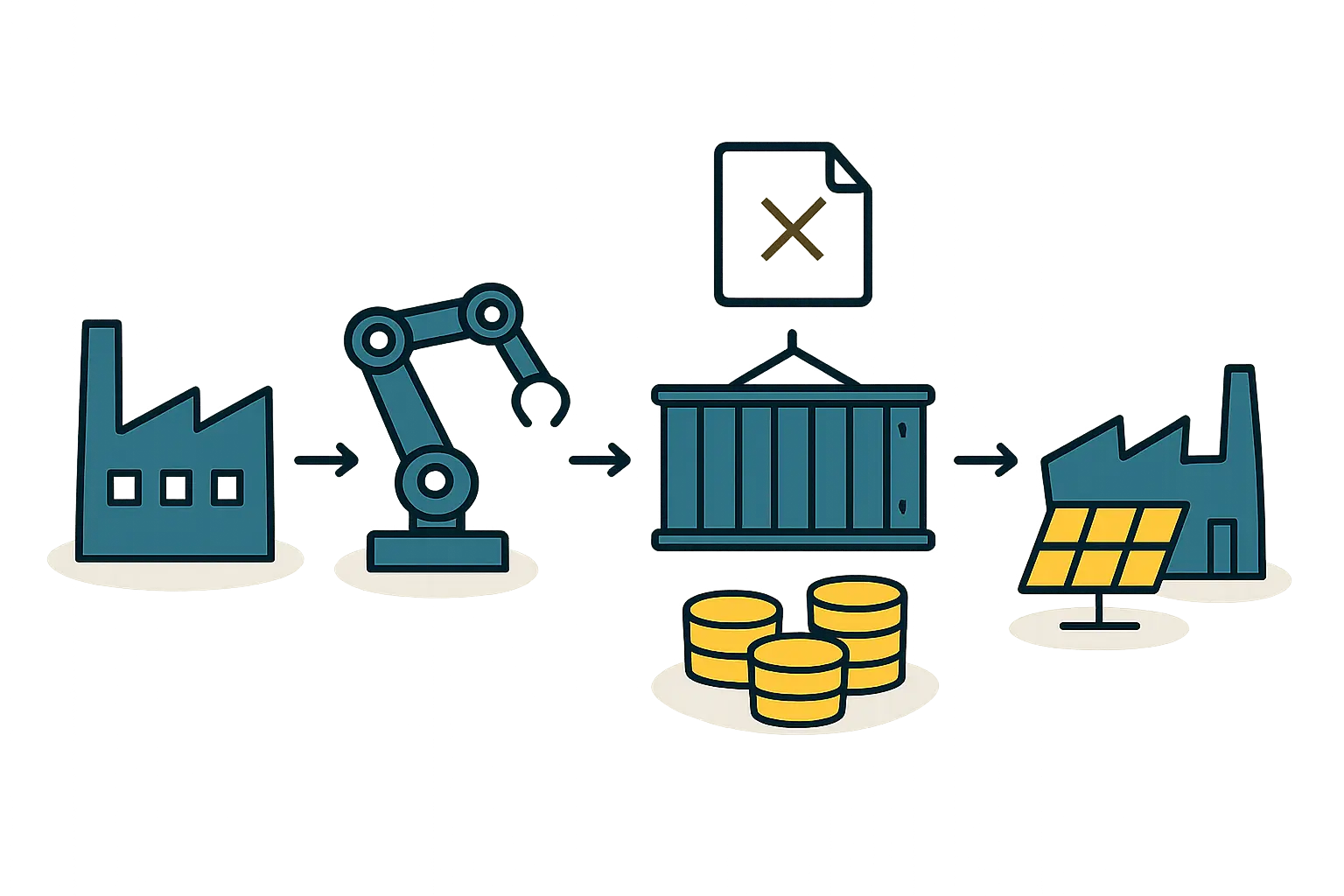

The Takasago Plant is the cornerstone of Kaneka’s strategy to refine and scale its organic solar technology. This facility bridges the crucial gap between laboratory research and full-scale commercial production. By producing modules on a pilot scale, the company can rigorously test and improve every aspect of the [solar panel manufacturing process], from efficiency and durability to cost-effectiveness.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

The pilot line, equipped with specialized [solar panel manufacturing machines], will focus on several key objectives. First is consistently achieving conversion efficiencies of 15% or higher in a production environment. Second is validating a 20-year operational lifespan. Finally, Kaneka aims to streamline the [basics of solar panel manufacturing] for OPV to drive down costs. By analyzing the entire [solar panel manufacturing plant cost breakdown], the company hopes to make its organic solar technology a financially competitive option in the global renewable energy market.

Kaneka’s Commitment to Renewable Energy and Organic solar modules

Kaneka’s investment in organic solar technology is a clear reflection of its broader commitment to sustainability and renewable energy. As a leader in developing advanced materials, the company’s work in OPV is a testament to its dedication to pushing the boundaries of what’s possible in energy generation.

The insights gained from the Takasago Plant’s pilot production will be invaluable. This data will inform Kaneka’s strategy for scaling up to mass production and successfully bringing these innovative organic solar modules to market. By focusing relentlessly on improving efficiency, durability, and cost, Kaneka is working to establish OPV as a truly viable and powerful alternative to traditional solar panels.

The Future of Organic solar modules Technology

Organic solar technology is poised to revolutionize the renewable energy sector. Its lightweight and flexible nature opens up a world of possibilities, from building-integrated photovoltaics (BIPV) that turn entire skyscrapers into power plants to portable solar chargers seamlessly integrated into backpacks and clothing.

This innovation is particularly relevant for the German market, where solutions like “Balkonkraftwerke” (balcony power plants) are gaining popularity. Lightweight, flexible OPV modules could make it even easier for tenants to generate their own electricity without permanent structural changes. The global market outlook reflects this excitement; the next-generation solar cell market is projected to reach USD 19.62 billion by 2032, with OPV and quantum dot technologies expected to grow at an impressive compound annual growth rate of 24.5%.

Kaneka’s pilot production is a significant leap toward realizing this future. As the company continues to refine its organic solar modules, it will be well-positioned to meet the surging global demand for versatile and sustainable energy solutions.

This pilot phase at the Takasago Plant is more than just a production trial; it’s a key milestone in the journey toward next-generation solar power. By balancing the goals of high efficiency, long-term durability, and competitive cost, Kaneka is bringing organic solar technology from the realm of possibility into the world of practical, commercial reality.

If you’re interested in learning more about the intricacies of solar technology production, consider enrolling in our [free e-course] to deepen your understanding.