An entrepreneur secures funding for a new solar module factory. He’s identified a promising location in Belarus—a region with a skilled workforce and strategic access to broader European markets. The business plan is solid, the technology is selected, and enthusiasm is high. Then, he runs into the dense web of environmental regulations, a critical step that was underestimated and now threatens to delay the entire project.

This scenario is all too common. For business leaders entering the solar manufacturing sector, particularly in jurisdictions like Belarus, the technical and financial aspects often overshadow the complex but non-negotiable requirements of environmental permitting. Navigating this landscape successfully is not just about avoiding fines; it is fundamental to the project’s timeline, budget, and its long-term license to operate.

This article provides a high-level overview of the factory environmental compliance and permitting process for a solar module manufacturing plant in Belarus, giving entrepreneurs the foundational knowledge to plan effectively and avoid costly surprises.

Table of Contents

Understanding the Belarusian Environmental Regulatory Framework

The cornerstone of Belarusian environmental law is the Law “On Environmental Protection.” This legislation establishes the state’s authority to control activities impacting the environment and sets the principles for resource use, pollution control, and ecological safety. All industrial projects, including solar panel manufacturing, fall under its jurisdiction.

The primary governing body is the Ministry of Natural Resources and Environmental Protection. This ministry, along with its regional branches, is responsible for reviewing applications, conducting expert assessments, issuing permits, and monitoring compliance.

Belarusian standards are increasingly harmonized with those of the Eurasian Economic Union (EAEU). This alignment means that compliance in Belarus can facilitate smoother trade and regulatory acceptance in other member states, such as Russia and Kazakhstan.

The Core Requirement: Environmental Impact Assessment (OVOS)

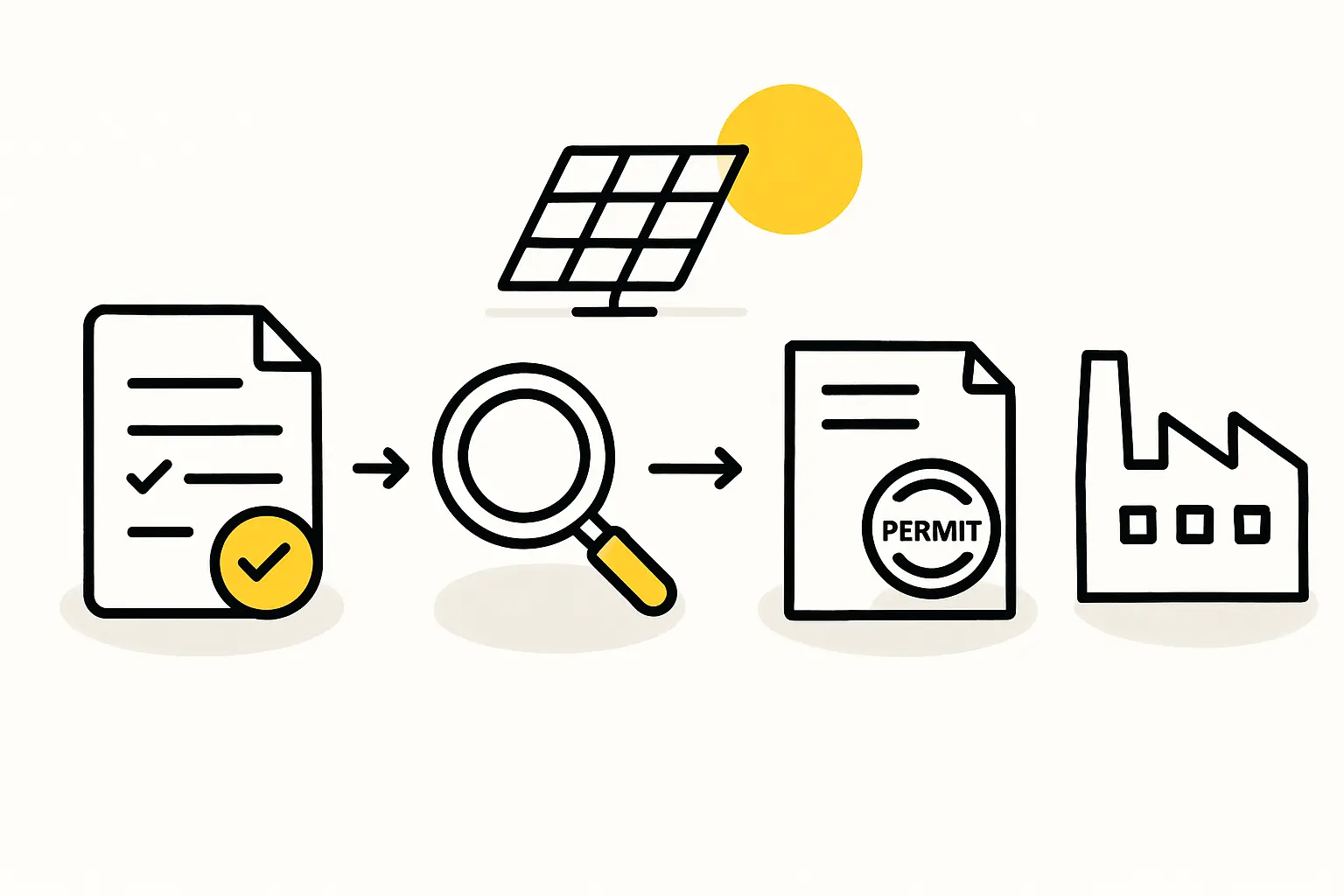

Before any construction can begin, a proposed industrial facility must undergo a mandatory State Ecological Expertise, which includes an Environmental Impact Assessment, known locally by the acronym OVOS (Оценка воздействия на окружающую среду). This is the most critical regulatory step in the pre-construction phase.

The OVOS process is a comprehensive evaluation of the factory’s potential environmental impact during its construction and operation—not a mere formality, but a rigorous, multi-stage procedure.

Typical Stages of the OVOS Process:

- Initial Application & Scoping: The project initiator submits a declaration of intent. The authorities then define the scope of the assessment, outlining the specific environmental aspects that must be studied in detail.

- Development of the EIA Report: The investor, typically working with a licensed local environmental consultant, prepares a detailed report. This document analyzes potential impacts on air, water, soil, and biodiversity and proposes mitigation measures.

- Public Consultations: The draft EIA report is made available for public comment. Public hearings are a mandatory part of this stage, providing a platform for local communities and stakeholders to voice concerns.

- State Ecological Expertise: The final EIA report, including feedback from public consultations, is submitted to state authorities for a formal expert review.

- Final Decision: Based on the review, the state issues a positive or negative conclusion. A positive conclusion is a prerequisite for obtaining a construction permit.

Experience from J.v.G. turnkey projects shows that a thoroughly prepared and professionally managed OVOS application is the single most critical factor in avoiding significant delays. Investors should budget 6 to 12 months for the entire process.

Key Areas of Environmental Scrutiny for a Solar Factory

While solar module assembly is considered a “clean” industry compared to heavy manufacturing, regulators will scrutinize several specific operational aspects.

Waste Management

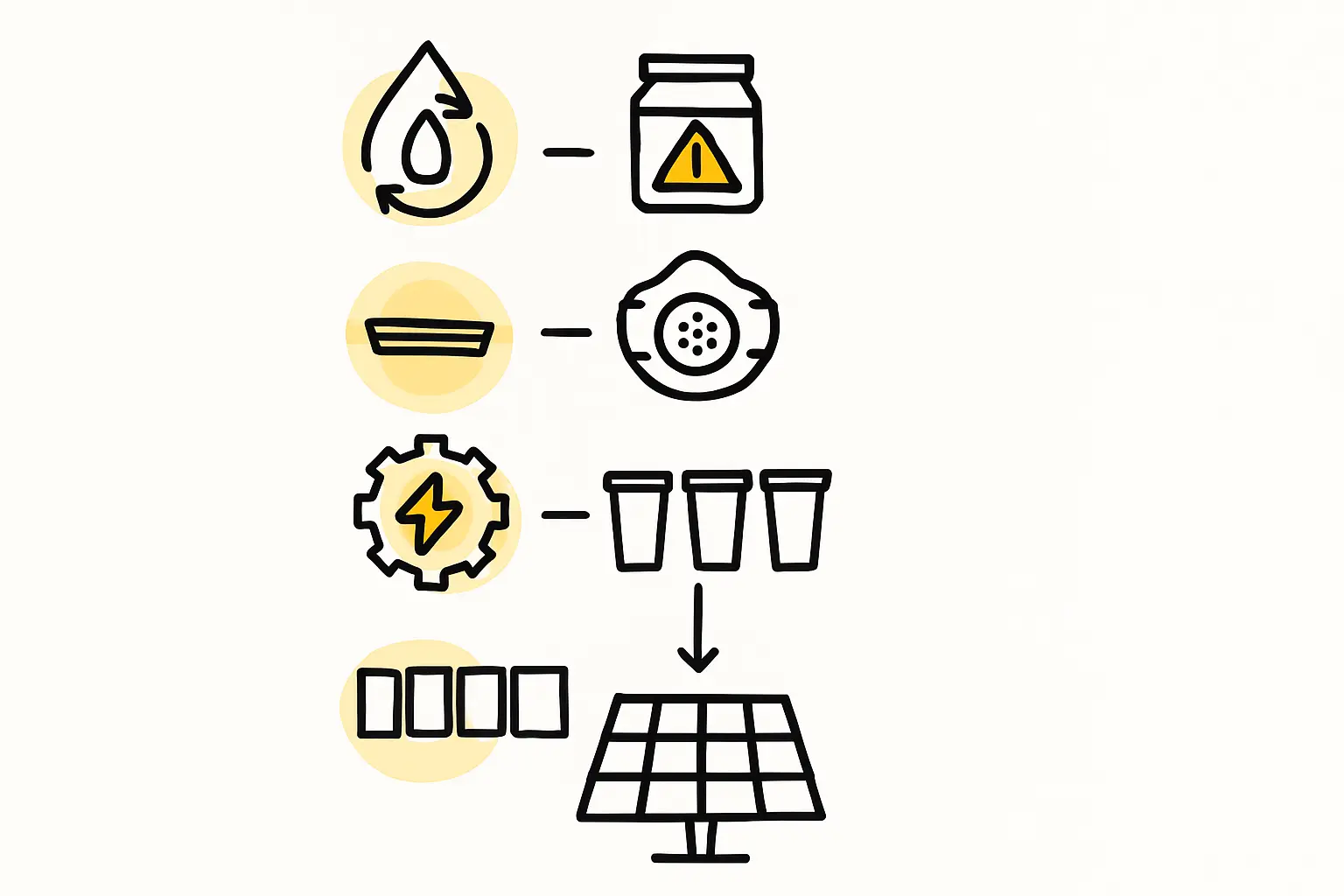

A solar factory generates several types of waste, and a comprehensive plan for managing them is essential. These materials fall into several categories:

- Non-hazardous waste: Packaging materials (cardboard, plastic), broken glass, and scrap aluminum frames.

- Production waste: Off-cuts of EVA (ethylene vinyl acetate) and backsheets.

- Hazardous waste: The most critical category, including lead-containing solder waste from stringer machines, used chemicals from cell cleaning processes, and contaminated cleaning materials.

The plan must detail how these materials will be segregated, stored, and transported for disposal or recycling by licensed contractors.

Water Usage and Wastewater Discharge

The manufacturing process requires water, primarily for washing solar cells before they are interconnected. While the volume may not be extensive, the facility must secure a permit for water use from local sources, such as the municipal supply or a well.

Any wastewater discharged from the plant must be treated to meet strict purity standards before release into the municipal sewer system or the environment. The OVOS report must detail the proposed water treatment technology.

Air Quality and Emissions

Air emissions are another area of focus. Potential sources include:

- Volatile Organic Compounds (VOCs): Released in small quantities from the lamination process as the EVA encapsulant is heated.

- Fumes: Generated during the soldering of cell strings and busbars.

A modern factory design incorporates ventilation and filtration systems to capture these emissions. The permit application must demonstrate that the facility’s air quality management systems will keep emissions well below legal limits.

Regulators in Belarus and similar jurisdictions are thorough, applying standards rigorously. The “green” nature of the final product does not grant the manufacturing process an exemption from scrutiny.

Securing the Integrated Environmental Permit (IEP)

Once the factory is operational, its ongoing environmental performance is governed by an Integrated Environmental Permit (IEP). Mandated by Presidential Decree No. 528, this permit consolidates requirements for air protection, water usage, and waste management into a single, comprehensive document.

One client in Eastern Europe, for instance, initially viewed the IEP as a bureaucratic burden. He later found that it simplified annual reporting and provided a clear compliance checklist for his operational team, making ongoing management more predictable.

Planning for Success: A Proactive Approach

The most effective strategy is to integrate environmental compliance into the project’s earliest stages. It should be treated not as a final hurdle but as an integral part of the facility’s design and business strategy.

For instance, the overall factory layout should be designed from day one to facilitate efficient waste segregation, safe chemical storage, and optimal placement of ventilation systems. A proactive approach not only demonstrates diligence to regulators but also often results in a more efficient and cost-effective operation in the long run.

Engaging with experts who understand both the technical requirements of a solar factory and the local regulatory environment is crucial. A turnkey factory solution provider, for example, often includes support for navigating these complex permitting processes as part of their scope.

Frequently Asked Questions (FAQ)

Q: Do these regulations apply even to a small (e.g., 50 MW) factory?

A: Yes. The principles of environmental protection and the requirement for an OVOS apply to all new industrial facilities. While the depth and complexity of the assessment may scale with the project’s size, the fundamental obligation to undergo the process remains.

Q: Is it possible to handle the permitting process without local expertise?

A: It’s highly challenging and not recommended. The Belarusian legal framework is complex, official documentation is in Russian or Belarusian, and the process requires interaction with multiple regional and national authorities. Engaging a licensed local environmental consulting firm is essential for an efficient and successful outcome.

Q: What are the consequences of non-compliance?

A: The consequences can be severe, ranging from substantial financial penalties to the suspension of operations. A history of non-compliance can also make it extremely difficult to secure permits for future expansions or projects.

Q: How does this process impact the project timeline and budget?

A: The permitting process significantly impacts both. A well-prepared business plan must account for a 6-to-12-month period for the OVOS and permitting phase before construction can begin. The budget should also allocate funds for local consulting fees, report preparation, and any required environmental monitoring equipment.

Q: Are there international standards we should consider?

A: While not mandatory for the initial permit, proactively designing the facility to align with international standards like ISO 14001 (Environmental Management Systems) can be highly beneficial. It strengthens the application, demonstrates a commitment to best practices, and improves long-term operational efficiency.

Conclusion: Building a Compliant and Sustainable Operation

Environmental compliance in Belarus is a rigorous but clearly defined process. For the international investor, it requires foresight, expert guidance, and a proactive mindset. By viewing these regulations not as obstacles but as a framework for building a high-quality, sustainable, and responsible business, entrepreneurs can lay a solid foundation for long-term success.

Understanding these nuances is the first step on a complex journey. The structured guidance available through pvknowhow.com is designed to demystify these topics, ensuring a new solar manufacturing project is built on solid ground—both technically and regulatorily.