When international entrepreneurs consider new locations for solar module manufacturing, countries like Bhutan may not immediately come to mind. Yet, a closer look reveals a compelling opportunity. The nation offers a unique combination of government support for renewable energy, a cost-effective operational environment, and, crucially, an untapped pool of young, educated, and motivated labor.

Harnessing this potential requires a clear understanding of the local labor landscape. An investor must move beyond surface-level assumptions and develop a practical strategy for building a skilled workforce from the ground up. This assessment is a critical early step in the factory planning process, transforming human capital from a potential challenge into a strategic asset.

Table of Contents

The Bhutanese Labor Landscape: An Untapped Opportunity

Bhutan’s economic story is one of careful, deliberate growth, guided by its unique philosophy of Gross National Happiness. The government is actively seeking to diversify its economy beyond hydropower and create meaningful employment for its young population. This creates a powerful alignment for investors in the growing **Bhutan manufacturing industry** and solar sector.

Key characteristics of the Bhutanese labor market include:

- A Youthful and Educated Workforce: With a youth unemployment rate of approximately 21%, a substantial number of educated young people are actively seeking stable, long-term employment. This translates into a ready supply of trainable candidates for technical roles.

- Government Priority on Job Creation: New industrial ventures that create skilled jobs are highly encouraged. A solar manufacturing facility directly supports national objectives for both economic diversification and sustainable development.

- Cultural Disposition: The Bhutanese workforce is known for its discipline, loyalty, and strong work ethic. In a factory environment where process adherence and quality control are paramount, these cultural traits are invaluable. Lower employee turnover is a common benefit, translating directly into reduced training costs and greater operational consistency.

Analyzing Core Skills and Identifying Gaps

While direct experience in photovoltaic manufacturing is rare in Bhutan, this is not a disqualifying factor. An investor’s focus should be on identifying candidates with strong foundational and transferable skills. Many young Bhutanese have completed secondary or vocational education, giving them a solid base in mathematics, basic sciences, and English, which is widely used in education and commerce.

The key is to build upon this foundation. The skills required for the various stages of the solar panel manufacturing process—from cell stringing to lamination and final testing—are primarily procedural and can be taught effectively.

The ideal candidate profile is not a seasoned expert but an individual who is detail-oriented, capable of following technical instructions, and committed to quality standards. A well-organized factory floor, with clear processes and supervision, can quickly turn this motivated but inexperienced workforce into a highly efficient production team.

Understanding Wage Structures and Labor Costs

Labor costs in Bhutan are globally competitive, offering a significant advantage for a manufacturing operation. According to official data, the national minimum daily wage rates provide a baseline for financial planning:

- Unskilled Labor: Approximately Nu. 125 per day (~$1.50 USD)

- Semi-skilled Labor: Approximately Nu. 150–200 per day (~$1.80–$2.40 USD)

- Skilled Labor: Approximately Nu. 200–300 per day (~$2.40–$3.60 USD)

These figures should be viewed as the legal minimum, not the target salary for a high-tech manufacturing facility. To attract and retain the best candidates from the educated youth demographic, a competitive compensation package is essential.

A realistic monthly salary for a factory operator or technician would likely fall in the range of $150 to $400 USD, depending on the role’s complexity and the individual’s qualifications. Even at this competitive level, the total labor cost remains significantly lower than in more established manufacturing hubs, strengthening the overall business case.

Designing an Effective Training Program: From Theory to Practice

Given the general lack of prior experience, a structured, comprehensive training program is the cornerstone of any successful solar manufacturing venture in Bhutan. This program shouldn’t be seen as a hurdle but as a strategic investment in building a capable, self-sufficient local team. Drawing on experience from J.v.G. Technology GmbH turnkey projects, a two-phase approach proves most effective.

Phase 1: Foundational Classroom Training

This initial phase, lasting one to two weeks, covers the theoretical knowledge required for all employees. Topics include:

- Workplace safety protocols

- Fundamentals of photovoltaic technology

- Principles of quality control and assurance

- Understanding the end-to-end production process

Phase 2: Hands-On Equipment Training

Following classroom instruction, the team moves to the production floor for practical, on-the-job training. This phase is led by experienced engineers and technicians, often from the equipment supplier. Each operator receives specific training on the machinery they will be responsible for, whether it’s a cell stringer, a laminator, or a sun simulator. Here, theoretical knowledge translates into practical skill.

A “train-the-trainer” model is highly recommended. By identifying promising local employees for advanced training, a business can build a core team of local supervisors and trainers. This approach ensures knowledge is retained within the company and reduces long-term reliance on expatriate experts. This entire training process is a standard component of a turnkey solar production line setup.

Frequently Asked Questions (FAQ)

Q: Is it difficult to find workers with technical backgrounds in Bhutan?

A: While finding individuals with prior solar manufacturing experience is rare, a large pool of young people hold secondary and vocational (TVET) qualifications. These candidates have the foundational literacy, numeracy, and problem-solving skills needed to excel in technical operator roles after training.

Q: What is the typical employee retention rate in Bhutan?

A: Bhutanese culture places a high value on loyalty and stability. Businesses that invest in their employees through fair wages, a positive work environment, and opportunities for growth typically experience very low employee turnover.

Q: Are there language barriers for international managers?

A: No, this is rarely an issue. English is the medium of instruction in Bhutanese schools and is widely spoken in business and official contexts, making communication between expatriate management and the local workforce clear and straightforward.

Q: How long does it take to train a new team for a solar factory?

A: A well-structured program can train a core team of operators to a proficient level within four to eight weeks. This includes both classroom theory and hands-on practice with the production equipment. Continuous skill development and cross-training should be an ongoing process.

Conclusion

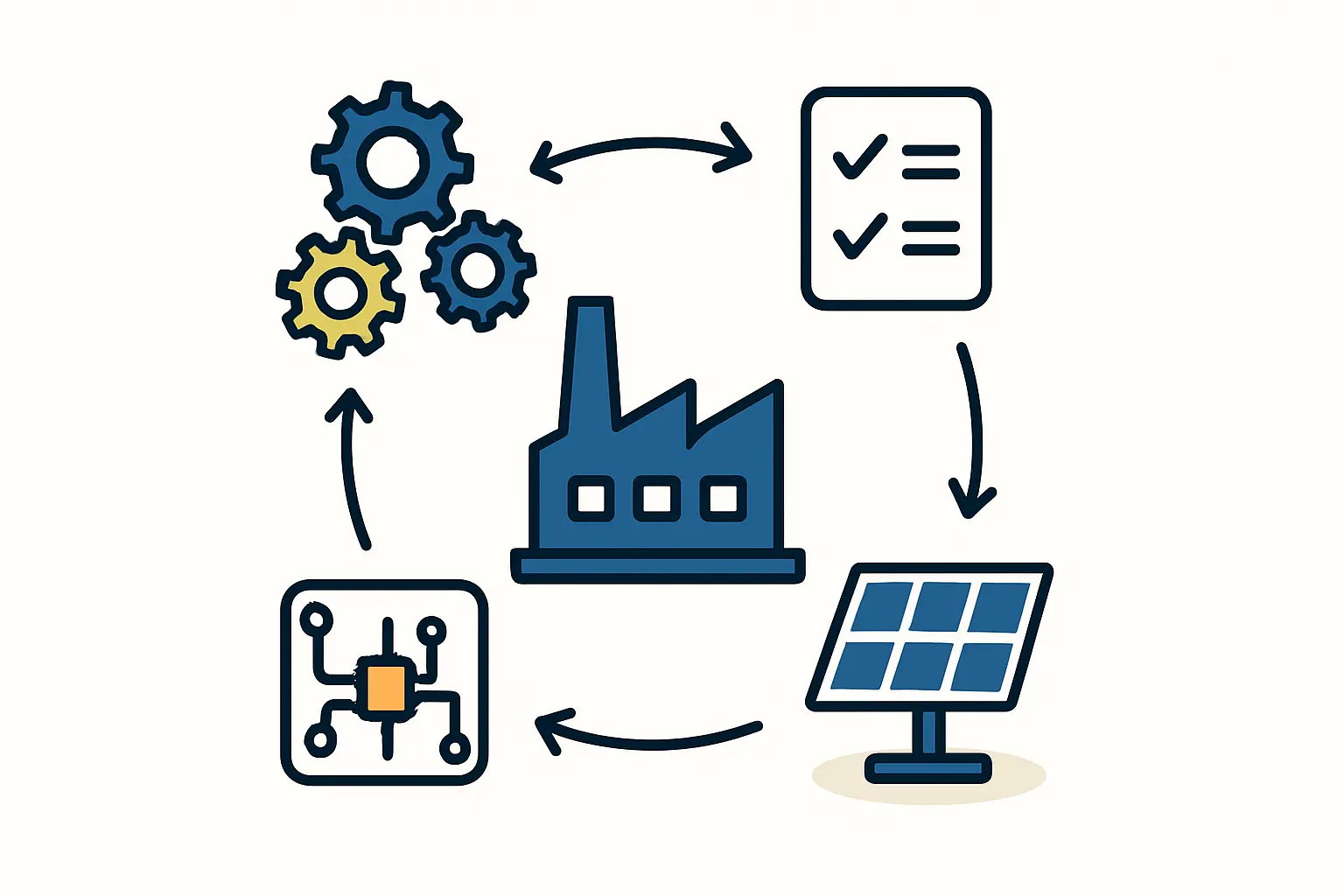

The Bhutanese labor market offers a compelling and often overlooked opportunity for solar manufacturing investors. The combination of a motivated, trainable workforce and a cost-effective environment provides a strong foundation for a successful enterprise. The key to success is a strategic approach that pairs investment in modern technology with an equal investment in people through robust, hands-on training.