For entrepreneurs looking to venture into solar module manufacturing, Bhutan offers a unique opportunity. As the world’s first carbon-negative country, its commitment to sustainability is backed by an abundance of clean, low-cost hydropower. This combination creates a compelling environment for green-tech industries. The success of such a venture, however, hinges on a single foundational decision: where to build the factory.

In a landlocked, mountainous nation like Bhutan, the choice of location is far more than a minor detail—it’s a strategic decision that defines supply chain efficiency, access to labor, and overall operational viability for new factories in Bhutan. This analysis offers a structured overview of the country’s primary industrial hubs, evaluating their suitability for a solar module factory based on critical business factors.

Table of Contents

Understanding Bhutan’s Industrial Landscape for Solar Manufacturing

Bhutan’s economic development is guided by the philosophy of Gross National Happiness, which emphasizes sustainable and equitable growth. For industrial investors, this translates to a focus on high-value, environmentally conscious projects.

The government, often through Druk Holding and Investments (DHI), actively encourages foreign direct investment (FDI) in sectors aligned with this vision, including solar manufacturing. New industrial projects are typically directed toward a designated Bhutan industrial area or park. These parks offer developed infrastructure, streamlined regulatory processes, and clear land-use policies, easing many of the initial setup challenges an investor might face. The strategic location of these parks—primarily along the southern border with India—is central to their value.

Core Criteria for Factory Site Selection

Before comparing specific locations, it’s essential to establish the key criteria for evaluating a potential site for a solar module factory. For a business operating in Bhutan, the following factors are paramount.

Proximity to Transport and Logistics Networks

Given that nearly all raw materials for solar module production must be imported—from solar cells and glass to encapsulants and aluminum frames—logistics are a critical driver of cost and efficiency.

A factory’s proximity to an efficient land port on the Indian border is non-negotiable. This access dictates the cost and speed of importing raw materials, which often arrive via the port of Kolkata, and exporting finished modules to the vast Indian market.

Availability of Skilled and Unskilled Labor

Solar module assembly requires a dedicated workforce. While much of the process is automated, the factory will still need operators, technicians, quality control personnel, and administrative staff. A site must be near a population center that can supply this workforce. The availability of technical training institutions and the ease of bringing in expatriate experts for initial setup and training are also crucial.

Access to Reliable Infrastructure

A key advantage for manufacturing in Bhutan is its surplus of hydropower, which provides reliable and competitively priced electricity—a significant operational cost for any factory. Beyond power, a viable site must have guaranteed access to water for processing and cooling, robust internet connectivity for modern manufacturing systems, and effective waste management facilities. These amenities are typically standard within planned industrial parks.

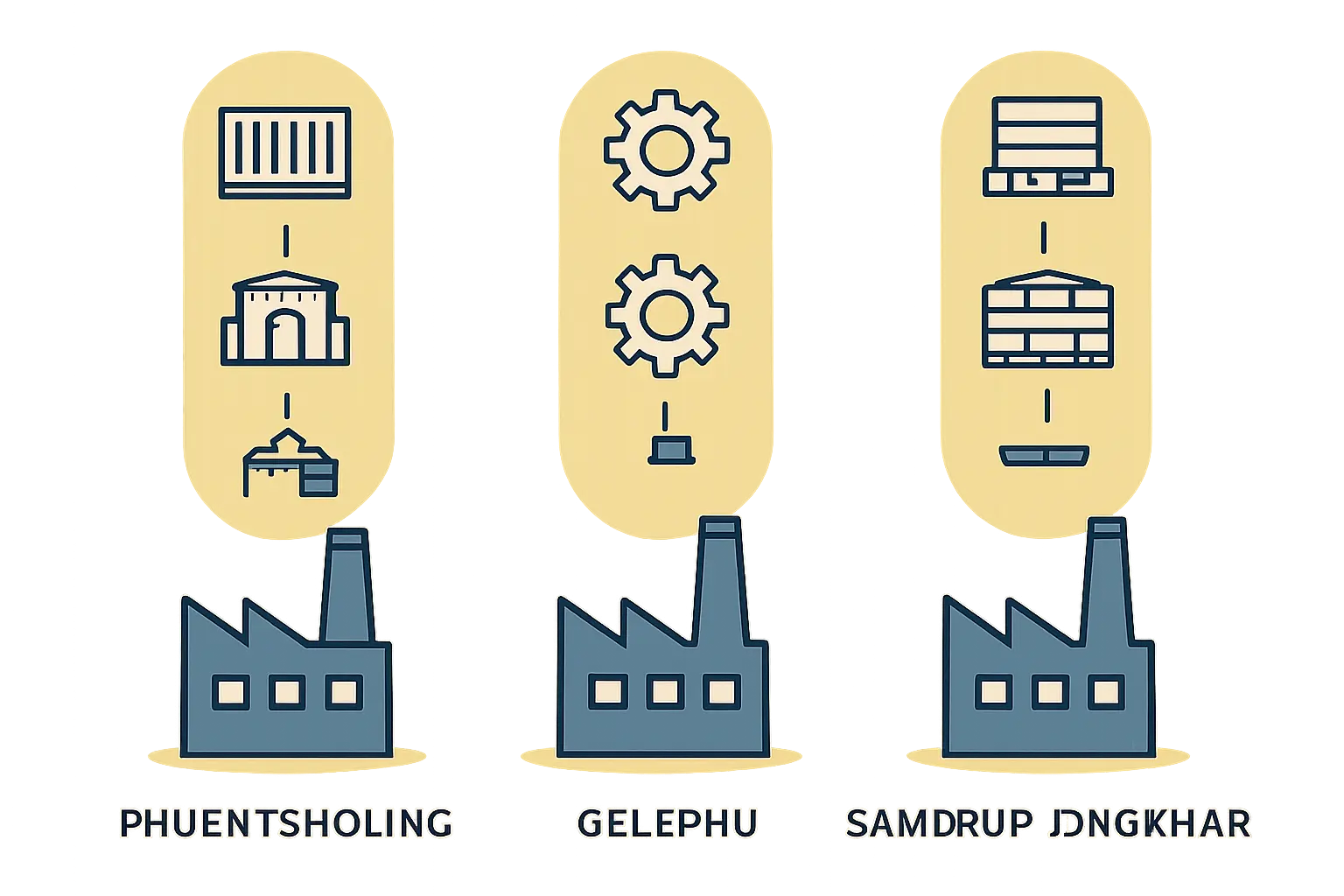

Comparative Analysis of Bhutan’s Primary Industrial Hubs

Bhutan’s southern border towns serve as the country’s economic conduits to India. Three locations, each with its own designated industrial parks, stand out as the most viable options for a new solar module factory.

Phuentsholing: The Established Commercial Gateway

As Bhutan’s primary commercial hub, Phuentsholing is the most developed and busiest border town, sharing a border with Jaigaon in West Bengal, India.

- Logistics: Its position as the main trade gateway ensures superior logistics, with well-established transport networks offering predictable transit for raw materials and finished goods.

- Infrastructure: The nearby Pasakha Industrial Estate is one of the country’s oldest and most developed manufacturing zones, providing reliable infrastructure.

- Labor: Phuentsholing’s larger, more diverse population provides a deeper labor pool to draw from compared to other regions.

- Considerations: Its established nature can also mean higher operational costs, greater competition for resources, and potential logistical congestion.

Gelephu: The Future Special Administrative Region (SAR)

Gelephu is at the heart of one of Bhutan’s most ambitious economic projects: the Gelephu Mindfulness City Special Administrative Region. This long-term vision positions the area as a future economic powerhouse.

- Logistics: It borders the Indian state of Assam, with plans for superior multimodal connectivity, including a potential new airport and railway links.

- Infrastructure: The area hosts the Jigmeling Industrial Park, designed to accommodate a range of industries. While some infrastructure is still under development, it is being built to modern standards.

- Labor: The government’s focus on Gelephu is expected to attract significant talent and investment, substantially growing the local labor market.

- Considerations: Investing in Gelephu is a strategic, forward-looking decision. An investor must balance the immense future potential against the current state of infrastructure, which is less mature than in Phuentsholing.

Samdrup Jongkhar: The Eastern Gateway

Located on the southeastern border with Assam, Samdrup Jongkhar is the main commercial hub for eastern Bhutan.

- Logistics: It provides strategic access to the markets of Northeast India, a rapidly developing region.

- Infrastructure: The town is home to the Motanga and Dhamdum Industrial Parks, which offer serviced land for new factories.

- Labor: The labor market is less developed than in Phuentsholing but offers potential cost advantages.

- Considerations: The logistical routes from Samdrup Jongkhar serve a different segment of the Indian market. The hub is generally considered less developed than Phuentsholing, presenting both challenges and opportunities.

Key Considerations Beyond Location

Selecting a city is only the first step. A comprehensive business plan must also account for several other interconnected factors that hinge on the chosen location.

Raw Material Supply Chain

The entire bill of materials for a solar module will be imported. A detailed analysis of the logistics chain from the port of Kolkata to each potential factory site is crucial.

This includes evaluating road conditions, transit times, customs clearance efficiency at each border crossing, and the reliability of transport operators. Any friction in this supply chain will have a direct impact on production schedules and costs.

Project Timeline and Implementation

The journey from decision to production involves many stages. Key steps in setting up the production line include site preparation, building construction, importing and commissioning machinery, hiring and training staff, and securing product certifications.

Based on experience from J.v.G. turnkey projects, this entire process can take between 9 to 12 months. The readiness of infrastructure within a chosen industrial park can significantly impact this timeline.

Frequently Asked Questions (FAQ)

Q: Why is Bhutan an attractive location for solar manufacturing despite its small domestic market?

A: The primary advantages are access to low-cost, 100% renewable energy (hydropower), strong government support for sustainable industries, and, crucially, strategic, duty-free access to the vast and growing Indian solar market.

Q: What is the typical size of a small-scale solar factory building?

A: A startup facility with a capacity of 20–50 MW per year typically requires a building with a floor area of 2,000 to 3,000 square meters. This size is well within the plot allocations available in Bhutan’s designated industrial parks.

Q: How does Bhutan’s hydropower advantage impact manufacturing costs?

A: Electricity is a significant operational expenditure in a solar module factory. The stable grid and competitive electricity tariffs in Bhutan can provide a substantial and sustainable cost advantage over manufacturing in regions that rely on more expensive or less reliable power sources.

Q: Are there specific incentives for foreign investors in these industrial parks?

A: Yes, Bhutan’s Foreign Direct Investment (FDI) policy typically includes a range of incentives to attract investment in priority sectors. These may include tax holidays, streamlined single-window clearances for licenses and permits, and other fiscal and non-fiscal benefits.

Conclusion: Making a Strategic Site Selection Decision

The optimal location for a solar module factory in Bhutan depends on an investor’s specific business strategy, risk appetite, and timeline.

Phuentsholing is the choice for investors prioritizing immediate market access and proven, established infrastructure.

Gelephu represents a long-term strategic investment, ideal for those looking to align with a major national development project and capitalize on future growth.

Samdrup Jongkhar offers a focused opportunity for businesses targeting the markets of Northeast India.

For a prospective investor, the next logical step is to conduct a detailed feasibility study. This study should involve on-the-ground assessments of each location, detailed logistical cost modeling, and direct engagement with Bhutan’s government agencies. Educational resources, such as the e-courses available on pvknowhow.com, can provide a structured framework for this detailed analysis, ensuring that this foundational decision rests on comprehensive data and strategic foresight.