An investor considering solar module manufacturing in Guatemala might initially focus on market demand and financial projections. But the country’s unique tropical environment presents an often-underestimated technical challenge: the climate itself.

A standard solar module designed for a temperate European climate simply won’t deliver the expected performance or lifespan when faced with Guatemala’s combination of intense sunlight, high humidity, and heavy rainfall. This mismatch can lead to premature failures, jeopardizing the long-term viability of a solar project.

Understanding how to design a module specifically for these conditions is not merely a technical detail; it is fundamental to a successful business strategy.

This guide explains the critical material and design choices required to produce durable, high-performance solar modules genuinely built for the Guatemalan climate.

Understanding Guatemala’s Climatic Challenges for Solar Technology

The Guatemalan environment, particularly in its coastal and lowland regions, creates a ‘triple threat’ for solar module components. Without the right design, each of these factors accelerates the degradation process.

High Humidity

Persistent moisture in the air is a primary adversary. Water vapor can slowly penetrate a module’s protective layers, leading to several issues. It can cause delamination—where the layers of the module separate—and corrode the metallic ribbons that conduct electricity. Moisture is also a key ingredient in Potential Induced Degradation (PID), a phenomenon that can significantly reduce a module’s power output.

Intense UV Radiation

As a country close to the equator, Guatemala receives high levels of ultraviolet (UV) radiation. Over time, UV rays break down the polymers used in many standard modules, particularly the backsheet and the encapsulant material surrounding the solar cells. This degradation manifests as yellowing, cracking, and brittleness, compromising the module’s protective shell and reducing its efficiency.

High Ambient Temperatures

While solar panels need sunlight, excessive heat reduces their operational efficiency. Materials expand and contract with temperature fluctuations, creating mechanical stress. A module designed for a moderate climate will experience accelerated material fatigue in consistently hot conditions.

The Critical Choice: Module Structure and Materials

Creating a climate-resilient solar module starts with its fundamental structure. The two dominant designs in the industry are the conventional glass-backsheet and the more robust glass-glass construction.

The Standard Approach: Glass-Backsheet Modules

The most common type of solar module features a sheet of tempered glass on the front, while a polymer-based backsheet protects the solar cells and encapsulant. This design is widely used due to its lower material cost and established manufacturing processes.

In a climate like Guatemala’s, however, this design has inherent vulnerabilities. The polymer backsheet, while designed to be durable, is not completely impervious to water vapor. Over a 20- to 25-year lifespan, slow but steady moisture ingress can lead to delamination and corrosion. The backsheet itself is also susceptible to UV degradation, which compromises its structural integrity.

The Robust Solution: Glass-Glass Modules

A glass-glass module, as the name implies, replaces the polymer backsheet with a second layer of heat-strengthened glass. This creates a hermetically sealed package, encasing the solar cells between two impermeable layers.

For the Guatemalan market, this design offers decisive advantages:

-

Superior Moisture Barrier: Glass is completely impermeable to water vapor. This effectively eliminates moisture-driven degradation like delamination and internal corrosion. It also significantly mitigates the risk of PID.

-

Enhanced UV Resistance: Glass is also highly resistant to UV radiation, ensuring the rear of the module remains protected throughout its service life without becoming brittle or discolored.

-

Increased Durability: The symmetrical structure provides greater mechanical stability, making the module more resistant to damage from handling, transport, and extreme weather.

This advanced construction makes glass-glass modules the superior choice for ensuring long-term performance and reliability in hot, humid environments.

Beyond the Glass: Encapsulants and Other Key Components

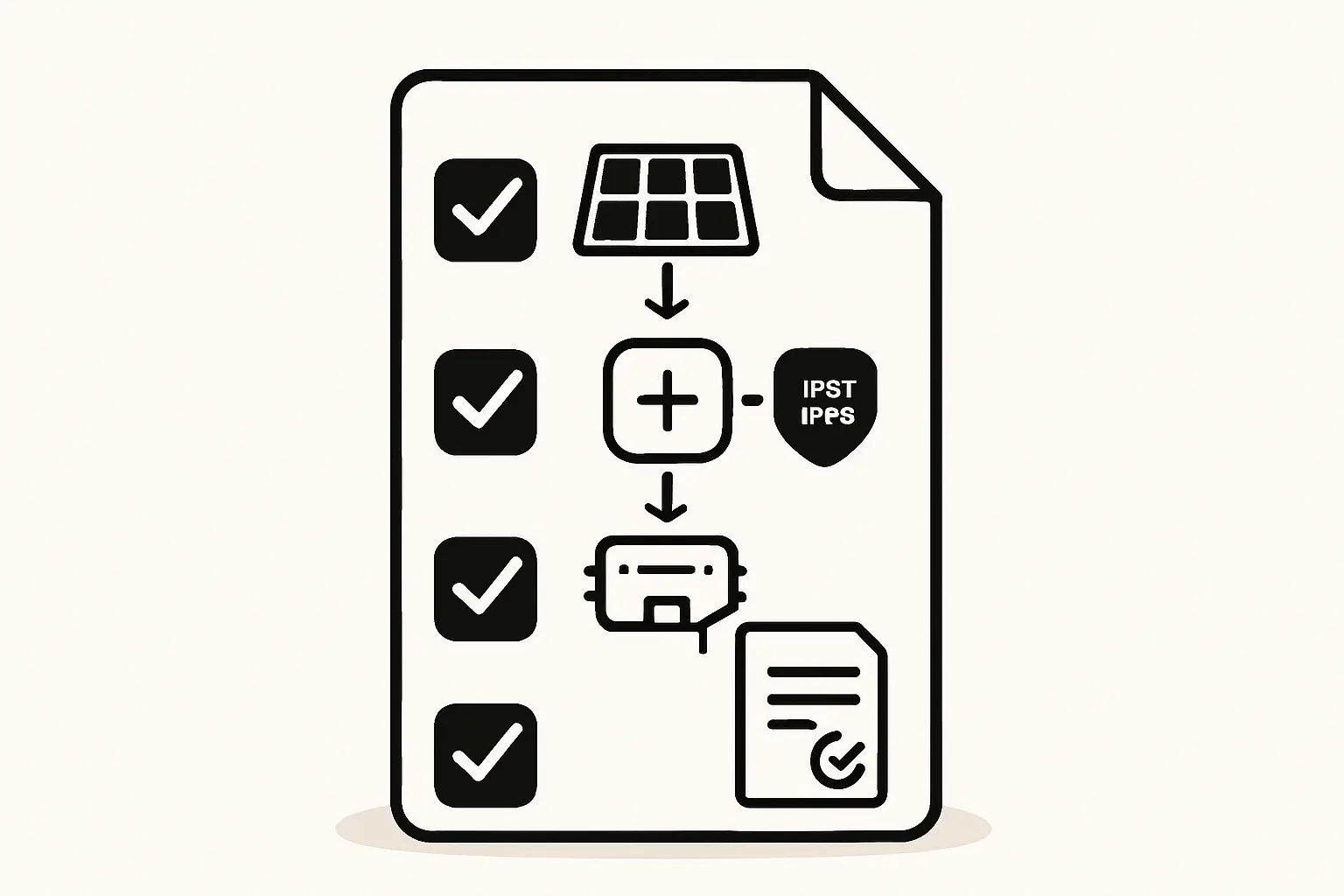

While the glass-glass structure is the foundation, the materials used within the module are equally important. The encapsulant—the transparent polymer that surrounds the solar cells—plays a critical role.

Traditionally, EVA (Ethylene Vinyl Acetate) has been the industry standard. However, a more advanced material, POE (Polyolefin Elastomer), offers significantly better performance in challenging climates. POE has a much lower water vapor transmission rate than EVA, adding another layer of moisture protection. It is also inherently resistant to PID, making it the ideal encapsulant for high-performance, long-lasting modules, especially within a glass-glass design.

Other components also demand careful selection. The junction box, for example, should have a high Ingress Protection (IP) rating like IP68 to prevent moisture from entering electrical connections. High-quality, corrosion-resistant aluminum frames are also essential.

Long-Term Performance and Investment Implications

Choosing robust materials and a glass-glass design typically involves a slightly higher initial investment in the production line. This decision, however, has a profound impact on the lifetime financial return of a solar project.

A module that degrades more slowly generates more electricity over its lifespan, which directly improves the Levelized Cost of Energy (LCOE)—a key metric for determining a project’s profitability. Manufacturing a product specifically designed for the local climate also becomes a powerful competitive advantage and builds a reputation for quality and reliability.

Understanding these material choices is a fundamental part of the overall solar module manufacturing process. For investors aiming to establish local production, a turnkey solar manufacturing line can be configured from the outset to produce these high-performance, climate-specific modules, ensuring the final product is genuinely built to last.

Frequently Asked Questions (FAQ)

Is a glass-glass module much more expensive to produce?

The material cost for the second sheet of glass is slightly higher than for a polymer backsheet. However, the manufacturing process is very similar, and the machinery can handle both types. The long-term return from lower degradation and a longer warranty period often justifies the marginal increase in initial cost.

Can standard modules from China or Europe be used in Guatemala?

They can be, but verifying the Bill of Materials (BOM) is critical. Many standard modules are not designed for tropical conditions and may experience premature failure. A locally produced module designed specifically for the climate offers greater assurance of performance and longevity.

What certifications are important for modules in humid climates?

Beyond standard certifications like IEC 61215, investors should look for evidence of extended reliability testing. This includes successful completion of extended Damp Heat tests (e.g., DH 2000 hours instead of the standard 1000 hours) and robust PID resistance testing.

Does the rear glass in a glass-glass module need to be the same as the front glass?

No. The front glass requires high transparency and often an anti-reflective coating to maximize light capture. The rear glass doesn’t need these features and can be thinner (e.g., 2.0 mm instead of 2.5 mm or 3.2 mm), which helps manage costs and weight.

Conclusion: Building for Longevity in the Guatemalan Market

For entrepreneurs and businesses entering the solar industry in Guatemala, success is not just about manufacturing a solar panel; it is about manufacturing the right solar panel. A module is a long-term asset, and its ability to withstand the local climate is paramount to its value.

By prioritizing a glass-glass design, selecting advanced materials like POE encapsulant, and ensuring all components are specified for high humidity and UV exposure, a manufacturer can produce a product that delivers reliable, clean energy for decades. This approach builds trust, ensures project bankability, and establishes a strong foundation for a sustainable business in Central America’s growing solar market.