An investor planning to build a solar module factory in Japan might envision a seamless operation, tapping into the country’s legendary reputation for engineering excellence and a diligent workforce.

The reality, however, is a paradox: while the potential for quality is immense, securing skilled labor is one of the most pressing challenges for any new industrial venture.

Successfully navigating this landscape requires more than just a competitive compensation package. It demands a deep understanding of Japan’s demographic shifts, cultural expectations, and the competitive pressures of its modern labor market. The right strategy provides a framework for building a resilient and highly skilled technical team for a new solar manufacturing facility in Japan.

The Unique Realities of Japan’s Labor Market

The foundation of any successful manufacturing operation is its people. In Japan, securing the right technical staff means navigating a market defined by two powerful, competing forces: a shrinking talent pool and an exceptionally high standard of skill.

With approximately 1.28 job openings for every applicant, Japan is a highly competitive environment for employers. The manufacturing sector feels this pressure acutely, with projections showing a potential shortfall of 384,000 workers by 2030. For a new solar factory, this means competing for engineers and technicians not only against other renewable energy companies but also against established giants in the automotive and electronics industries.

At the same time, the workforce is renowned for its commitment to monozukuri—a term that encapsulates the Japanese spirit of craftsmanship, precision, and the continuous pursuit of quality. While this dedication is a tremendous asset for producing high-performance solar modules, it also means the most capable individuals are in very high demand.

Key Challenges for New Solar Factory Operators

An effective labor strategy starts with a clear-eyed assessment of the obstacles. For any company entering the Japanese market, three primary challenges stand out.

The Demographic Hurdle: An Aging Workforce

Japan has one of the world’s oldest populations, with over 29% of its citizens aged 65 or older—a trend that directly impacts the manufacturing workforce. The median age of skilled technicians and engineers is rising, leading to a gradual loss of institutional knowledge as experienced professionals retire.

For a new factory, this means that hiring only experienced staff is not a sustainable long-term strategy. A plan for knowledge transfer, succession, and developing younger talent is essential for ensuring operational excellence for years to come.

Cultural Dynamics: Loyalty, Seniority, and Wages

The tradition of lifetime employment (shūshin koyō), while less rigid than in past generations, still influences workplace culture. Many senior professionals expect stability and a clear, seniority-based career path. While younger workers are increasingly open to changing jobs for better opportunities, the cultural expectation of loyalty often remains.

Japan has also experienced decades of relatively stagnant wage growth. Though this may seem like an advantage, it means that attracting top talent requires more than a high salary. Prospective employees will closely evaluate a company’s culture, opportunities for professional development, and long-term vision.

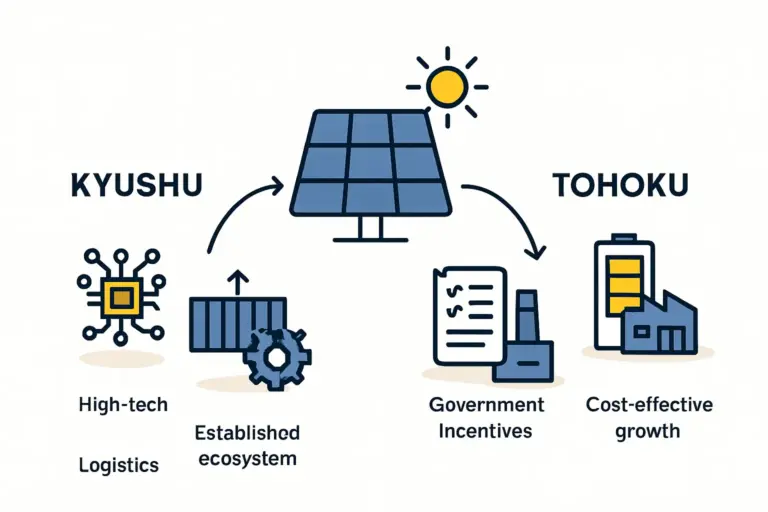

Fierce Regional Competition for Talent

Competition for skilled labor varies widely across the country and is particularly intense in established industrial hubs around Tokyo, Nagoya, and Osaka. New ventures may find more success by establishing operations in prefectures that have a strong industrial base but less competition from major corporations. This strategy, however, requires careful research into local talent pools, partnerships with regional technical colleges, and a compelling value proposition to attract individuals to the area.

Strategic Approaches to Building a Skilled Team

Overcoming these challenges requires a multifaceted approach that combines modern recruitment techniques with a deep respect for local business culture.

Rethink Recruitment: A Targeted Approach

Broad-based job postings are often less effective than a more targeted strategy. This includes:

-

Partnering with Universities: Establishing relationships with engineering and technical universities can create a pipeline of young, motivated graduates.

-

Focusing on a Strong Value Proposition: Communicate what makes the company unique. For many, the mission of advancing renewable energy is a powerful motivator that transcends salary alone.

-

Highlighting Growth Opportunities: Demonstrate clear paths for advancement and skill development, appealing to the career ambitions of both younger and mid-career professionals.

Integrate Automation as a Core Labor Strategy

In a labor-scarce market, automation is not just an efficiency tool; it is a strategic necessity. By investing in a highly automated production line, a factory can reduce its dependency on manual labor for repetitive tasks. This allows the team to focus on higher-value roles such as quality control, maintenance, and process optimization. A modern approach to automation in solar manufacturing is fundamental to mitigating labor risks and ensuring consistent output.

Develop a Blended Workforce Plan

A successful strategy often involves a blend of different talent pools:

-

Senior Experts: Hire a core team of experienced Japanese engineers to establish quality standards and mentor junior staff.

-

Young Graduates: Recruit from technical colleges and universities to build a sustainable talent pipeline.

-

Foreign Specialists: Consider hiring foreign experts with specific solar manufacturing experience, especially for initial setup and training. This approach requires a robust plan for integration, including language support and cultural orientation.

Experience from J.v.G. turnkey projects shows that early, detailed labor planning is one of the most critical success factors when starting a solar factory in a sophisticated market like Japan. Understanding the necessary solar factory labor structure from the outset helps prevent costly delays during the crucial ramp-up phase.

Frequently Asked Questions (FAQ)

- What are the most critical roles to hire first for a new solar factory in Japan?

The first key hires should be a Plant Manager with experience in Japanese manufacturing environments and a Head of Engineering or Quality. These individuals will be instrumental in setting up the facility, defining processes, and building the rest of the technical team.

- How long does it typically take to recruit a core technical team in Japan?

Given the competitive market, plan for 6 to 12 months to recruit and onboard a core team of 5–10 engineers and senior technicians. The process requires patience and a thorough vetting process.

- How important is the Japanese language for technical and management staff?

For management and roles that interface with local suppliers, regulatory bodies, and the workforce, business-level fluency in Japanese is essential. While some engineering roles might be filled by non-Japanese speakers, a lack of language proficiency can create significant communication barriers and hinder effective team integration.

- Are foreign technical qualifications recognized in Japan?

Generally, engineering degrees and technical certifications from reputable international institutions are well-regarded. However, employers will place a strong emphasis on practical experience, particularly within a manufacturing context. The final hiring decision often rests on a candidate’s demonstrated skills and cultural fit.