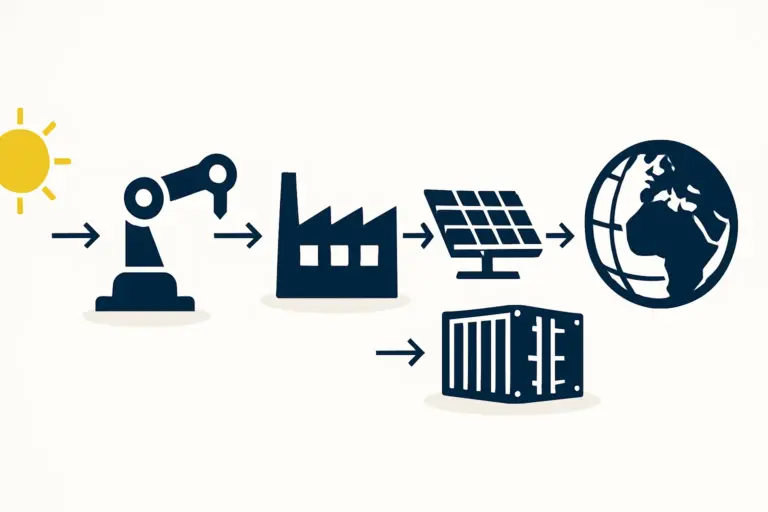

For any family office or established business, diversification is a cornerstone of long-term growth. Yet entering a technically complex industry like renewable energy manufacturing can be daunting.

This raises a central question: How can a non-technical investor successfully launch a manufacturing operation in a high-growth sector without prior engineering expertise?

This article outlines a real-world scenario, detailing a turnkey project for establishing a 30 MW solar module factory near Casablanca, Morocco. It’s a blueprint for how a strategic partnership can transform a complex industrial project into a manageable and profitable venture.

The Opportunity: A Niche in Morocco’s Growing Energy Market

While global solar manufacturing is dominated by large-scale producers, significant opportunities exist for specialized, local players. Morocco, with its ambitious renewable energy targets and high solar irradiation, presents a compelling case for domestic production.

For a new entrant, the goal isn’t to compete on the global stage, but to serve the rapidly expanding local demand for rooftop and commercial solar installations.

A local factory offers distinct advantages:

- Reduced Logistics Costs: Eliminates expensive international shipping and import tariffs.

- Faster Delivery: Provides a responsive supply chain for local project developers.

- Tailored Products: Enables the production of modules specifically designed for regional climate conditions.

- Economic Contribution: Fosters local job creation and technical skill development.

By focusing on a premium domestic market, a ’boutique’ factory can build a strong brand on quality and local presence, sidestepping direct competition with commodity producers.

The Business Model: A 30 MW High-Efficiency Boutique Factory

A 30 MW annual production capacity is a strategic entry point. It’s substantial enough to achieve economies of scale for profitability, yet focused enough to maintain meticulous quality control and adapt to market needs.

Key Parameters of the Model:

- Annual Capacity: 30 Megawatts (MW). This translates to approximately 75,000 to 85,000 solar modules per year, depending on the specific wattage.

- Target Market: High-end residential rooftops and commercial and industrial (C&I) projects within Morocco and the surrounding region.

- Product Focus: Premium DESERT+ solar modules, engineered for optimal performance and durability in hot, arid climates.

At the core of this model is a specialized product: the DESERT+ modules. They use high-efficiency Passivated Emitter and Rear Cell (internal link to: what are PERC solar cells?) technology to offer superior energy yield in the high-temperature environments common in North Africa. This focus on quality and climate-specific engineering creates a powerful unique selling proposition.

The Turnkey Solution: A De-Risked Path to Market Entry

The most significant barrier for a new investor is execution risk. A turnkey solution, managed by an experienced engineering partner like J.v.G. Technology GmbH, mitigates this by providing a single point of responsibility for the entire setup process.

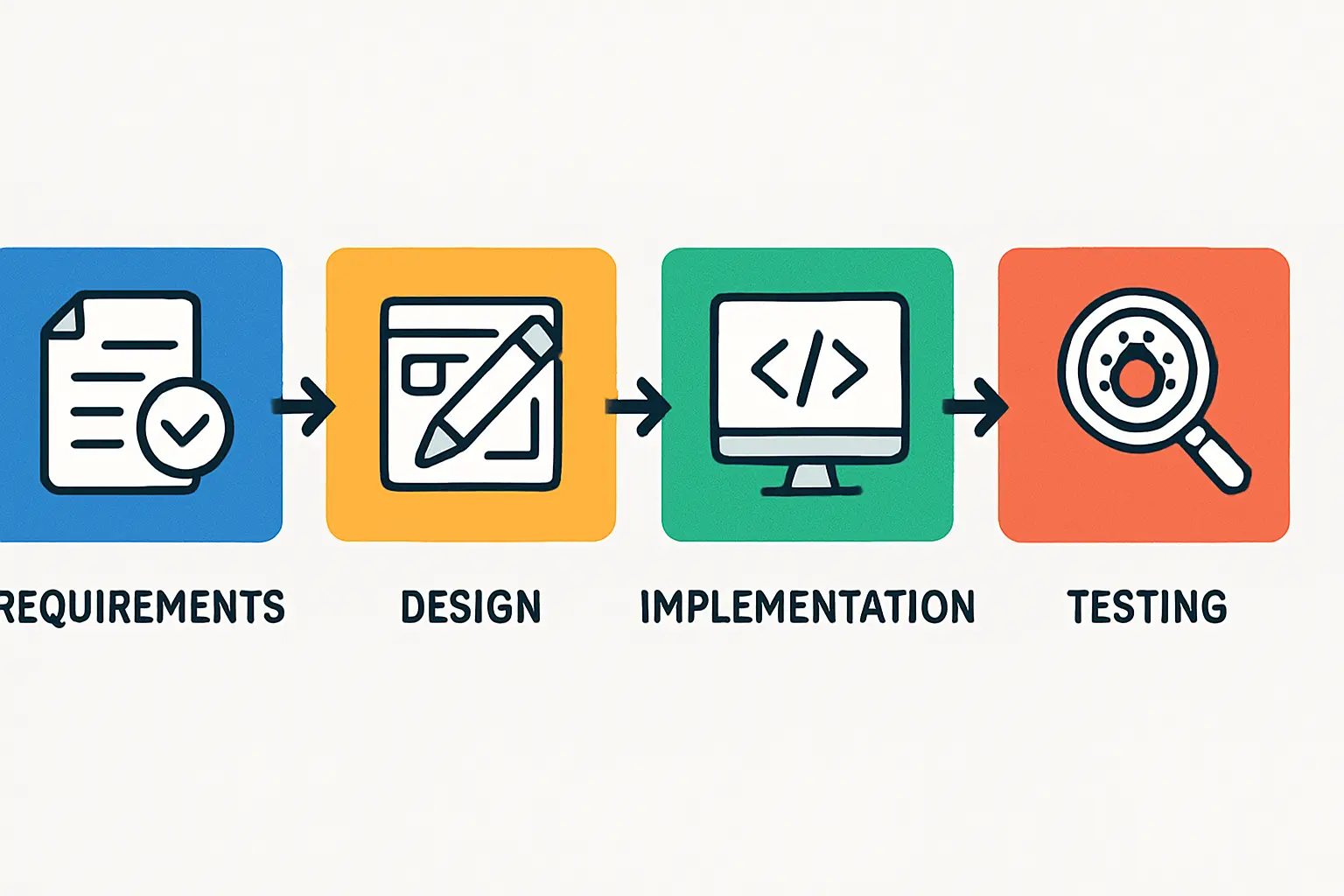

The process, drawn from J.v.G.’s experience with similar turnkey projects, is structured, transparent, and typically completed within 12 months.

Phase 1: Planning and Factory Design

The foundation of an efficient factory is its layout. This phase involves designing the process flow, specifying infrastructure requirements like electricity, compressed air, and climate control, and creating a blueprint that optimizes material movement and minimizes waste.

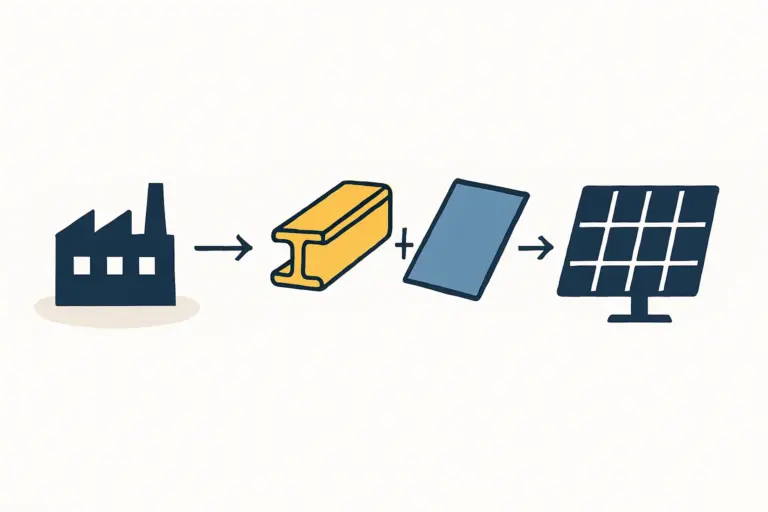

Phase 2: Equipment and Investment

The total turnkey equipment investment for a 30 MW line like this is approximately €1.5 million. This figure covers the procurement, shipping, installation, and commissioning of all necessary production and testing machinery. A detailed breakdown of the required capital is a crucial component of the initial business plan. More information can be found in this guide to (internal link to: investment requirements for solar manufacturing).

Phase 3: Installation and Commissioning

An experienced team manages the entire installation on-site, ensuring every machine is correctly set up, calibrated, and integrated into the production line. This phase concludes with the production of test modules to verify the entire line operates at specified quality and throughput levels.

The Thoma Family Guarantee: A Unique Layer of Support

What distinguishes this model is the direct involvement of the founding family behind J.v.G. Technology. With over 30 years of hands-on experience in solar manufacturing, the Thoma family provides ongoing management consulting during the critical start-up phase.

This ‘expert-on-demand’ support system is invaluable for a non-technical owner, offering guidance on everything from supply chain management to quality control protocols.

The Human Element: Building a Competent Local Team

Technology alone doesn’t guarantee success. The operational team is the heart of the factory. A 30 MW facility typically requires a workforce of 25–30 people, including line operators, maintenance technicians, and quality assurance staff.

Comprehensive operator training is a critical part of the turnkey package. This isn’t just a machine manual; it’s a hands-on program designed to build a skilled and self-sufficient local team.

The training covers:

- Safe and efficient operation of all machinery.

- Standard operating procedures for quality control at each production step.

- Basic maintenance and troubleshooting.

- Understanding the properties of raw materials.

This investment in human capital ensures the factory can maintain high production standards long after the engineering partners have completed their work.

FAQ for Aspiring Solar Entrepreneurs

Why a 30 MW capacity? Why not start larger?

A 30 MW line offers the best balance of manageable investment, operational simplicity, and profitability for a new market entrant. It allows the business to establish a premium brand and secure a loyal customer base before considering future expansion.

What are the main challenges for a new solar module manufacturer?

The top three challenges are typically quality control, supply chain reliability, and product certification. A turnkey partner helps mitigate these by implementing proven quality assurance systems, providing a vetted list of raw material suppliers, and guiding the factory through the necessary (internal link to: guide to solar module certifications) process (e.g., IEC 61215).

Is a technical background essential for the owner or investor?

No. While technical curiosity is beneficial, a background in business management, finance, or logistics is equally valuable. The key is to partner with a technical expert who can manage the engineering aspects, allowing the owner to focus on strategy, sales, and business development.

What makes a DESERT+ module different from a standard module?

DESERT+ modules are specifically engineered with materials and design features that improve performance and resist degradation in environments with high temperatures, high UV radiation, and arid conditions. This can include specialized encapsulants, backsheets, and cell technologies that maintain higher efficiency as temperatures rise.

Conclusion: A Structured Path to a High-Growth Industry

For a family office or strategic investor in a region like North Africa, entering the solar manufacturing sector is a viable and attractive proposition. The key is to reframe the challenge: it’s not about becoming a technical expert overnight, but about finding the right partner to provide a structured, de-risked pathway.

The 30 MW turnkey factory model in Casablanca serves as a practical blueprint, combining a manageable investment, a focused business strategy, proven technology, and expert guidance to create a robust foundation for success. With this approach, diversifying into renewables is no longer an insurmountable technical hurdle but a clear strategic opportunity.