An entrepreneur invests in a state-of-the-art solar module assembly line in a UAE free zone. The factory is efficient, the team is well-trained, and the first batch of modules passes international testing with flying colors, earning the coveted IEC certification.

He’s ready to supply the booming local market, but when he approaches a major developer in Dubai, he’s told his modules can’t be used. The reason? Despite having global certification, he missed the critical local and utility-specific compliance steps.

This scenario is more common than many new entrants realize. Manufacturing a high-quality solar panel is only half the battle. To unlock market access within the UAE and abroad, you must prove its quality through a multi-layered system of certification and compliance.

This article breaks down the essential quality, certification, and compliance framework that solar module manufacturers in the United Arab Emirates must navigate. Understanding this landscape from the outset is crucial for building a successful and sustainable business.

The Three Tiers of Solar Module Compliance

New manufacturers should view compliance not as a single hurdle, but as a three-tiered structure. Each serves a different purpose and unlocks a different market. A strategic approach means addressing all three in the correct sequence.

- International Standards: The global passport for credibility and export.

- National Requirements: The legal key to sell within the UAE domestic market.

- Utility and Project-Specific Mandates: The requirement for supplying large-scale, grid-connected projects.

Navigating these tiers successfully requires more than a quality product; it demands a robust quality management system integrated into the production line from day one.

Tier 1: International Standards – The Global Passport (IEC & UL)

Before a module can be considered for any market, it must prove its quality and safety against globally recognized benchmarks. These standards are not a mere formality—they are the result of decades of research into what makes a solar module reliable and safe over its 25-year lifespan.

The primary international standards body is the International Electrotechnical Commission (IEC). The two most critical standards for a crystalline silicon module manufacturer are:

-

IEC 61215: “Terrestrial photovoltaic (PV) modules – Design qualification and type approval.” This standard tests the module’s performance under various stress conditions, such as thermal cycling (hot to cold), humidity and freezing, and mechanical load (to simulate wind and snow).

-

IEC 61730: “Photovoltaic (PV) module safety qualification.” This standard focuses on protecting against electrical shock, fire hazards, and personal injury. It ensures the module is constructed safely with proper insulation and materials.

Achieving these certifications from an accredited third-party laboratory is non-negotiable. It’s the fundamental proof of quality that underpins all other compliance efforts. For manufacturers targeting the North American market, the equivalent standards from Underwriters Laboratories (UL) are also required.

Based on experience from J.v.G. turnkey projects, planning for IEC certification should begin at the factory planning stage. The choice of materials and equipment for your production line directly impacts the likelihood of passing these stringent tests on the first attempt.

Tier 2: National Requirements – The UAE Market Access Key (ECAS/MOIAT)

While IEC certification is globally respected, it doesn’t automatically grant the right to sell products within the UAE. To legally sell products in the country, manufacturers must also comply with national regulations.

The governing body is the Ministry of Industry and Advanced Technology (MOIAT), which absorbed the functions of the Emirates Authority for Standardization and Metrology (ESMA). MOIAT operates the Emirates Conformity Assessment Scheme (ECAS).

ECAS is a mandatory program that ensures products entering the UAE market meet national standards for safety and quality. For solar modules, this typically involves:

- Submitting Valid IEC Test Reports: The IEC 61215 and IEC 61730 test reports from an accredited lab serve as the core technical evidence.

- Providing Documentation: This includes a declaration of conformity, business license, and detailed product information.

- Factory Audit (in some cases): MOIAT may require an inspection of the manufacturing facility to verify that quality control processes are in place.

Upon successful review, a Certificate of Conformity is issued, allowing the product to carry the Emirates Quality Mark (EQM). This mark signals to regulators, distributors, and customers that the product is legally compliant for sale in the UAE.

Failing to secure this certification can result in products being blocked at customs or removed from the market.

Tier 3: Utility & Project-Specific Mandates (DEWA)

The final tier of compliance is often the most crucial for manufacturers aiming to supply large-scale projects in the UAE. Major utilities run their own pre-qualification programs to ensure that any equipment connected to their grid meets exceptional standards for reliability and performance, especially given the region’s harsh climate.

The most prominent example is the Dubai Electricity and Water Authority (DEWA). To be used in any solar project connected to Dubai’s grid, a module must be on the “DEWA Approved Solar PV Equipment” list.

Getting on this list involves a separate application process directly with DEWA. The review covers:

- IEC and ECAS Certifications: These are prerequisite documents.

- Manufacturer’s Track Record: DEWA assesses the company’s experience and production stability.

- Specific Climate Data: Test results proving the module’s performance in high-temperature, high-humidity, and high-irradiance conditions relevant to the Dubai environment. This is why choosing the right solar panel technology for the target climate is critical.

DEWA’s stringent requirements are in place to safeguard the long-term stability of its grid and the financial viability of these multi-million-dollar solar projects. Similar standards are often applied by other major developers in the region, such as Masdar in Abu Dhabi.

A Common Pitfall: The Certification Timeline

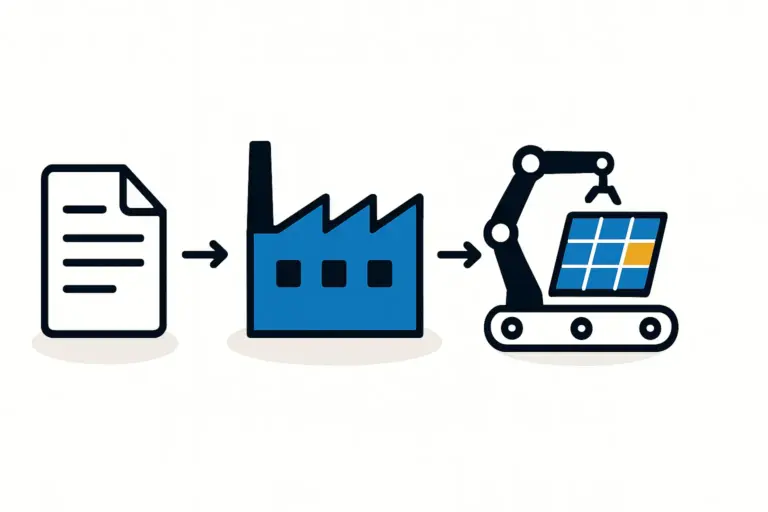

A common pitfall for new entrepreneurs is underestimating the time this multi-layered certification process takes. It isn’t a process that can be completed in a few weeks. A realistic timeline must be factored into the business plan:

- Months 1-8: Factory setup, commissioning, and pilot production runs.

- Months 9-12: Sending sample modules to an accredited lab for full IEC/UL testing. This process itself can take 3-6 months.

- Month 13: Upon receiving positive IEC test reports, the application for ECAS/MOIAT certification can begin.

- Months 14-16: After securing ECAS, the application for DEWA listing can be submitted.

This sequence demonstrates that achieving full market access can take well over a year from the start of production. Factoring this timeline into the business plan from day one is essential for preventing cash flow problems and managing investor expectations.

Frequently Asked Questions (FAQ)

Do I need all three tiers of certification to start my factory?

You need a plan for all three, but they are sequential. IEC certification is the first and most fundamental step. Your next priority depends on your target market. If you plan to export immediately, IEC/UL certification is sufficient. For local sales within the UAE, ECAS is mandatory. For large projects in Dubai, DEWA approval is essential.

Can I use a single test for all certifications?

The IEC 61215 and 61730 test reports serve as the technical foundation for the other applications. You don’t need to re-test the modules for ECAS or DEWA, but these bodies do require additional documentation, application forms, and potentially a factory inspection.

What is the difference between factory certification and module certification?

Module certification (like IEC 61215/61730) tests the final product. Factory certification, such as ISO 9001, assesses the quality management processes of the entire facility. While not always mandatory, having ISO 9001 is highly recommended, as it demonstrates a commitment to consistent quality and often simplifies the module certification process.

How much does module certification cost?

The cost for a full IEC certification sequence from a top-tier laboratory can range from $50,000 to over $150,000 USD per module family. Costs vary depending on the lab, the specific tests required, and whether re-testing is needed. This investment should be included in your initial financial planning.

Your Path to a Compliant Solar Manufacturing Operation

Success in the UAE’s competitive solar manufacturing sector is built on a foundation of proven quality. This proof lies not just in the product itself, but in the certified documentation that validates its performance, safety, and compliance with international, national, and utility-specific standards.

By understanding this three-tiered framework and making the certification journey a core part of their business strategy, entrepreneurs can avoid costly delays and position their operations for sustainable growth.

For professionals planning to enter this market, pvknowhow.com offers structured educational resources detailing each step of the process, from initial business planning to final certification.