Qcells has announced plans to complete the integration of its Georgia solar panel factory by early 2026, a landmark move that will establish the first fully domestic solar supply chain of its kind in the United States and significantly increase the nation’s production capacity.

Expansion of the Qcells Georgia solar factory

Qcells—a subsidiary of the South Korean industrial conglomerate Hanwha Group—is solidifying its role in the American renewable energy landscape with a massive expansion in Georgia. The company is upgrading its existing factory in Dalton, Georgia, aiming to nearly double its production capacity from 1.7 GW to 3.1 GW per year by the end of 2024. This initial expansion is set to create 600 new jobs in Whitfield County.

In addition, Qcells is constructing a new, state-of-the-art facility in Cartersville, Georgia. This plant will add another 3.1 GW to the company’s annual production capacity, bringing its total U.S. module output to a staggering 8.4 GW. This strategic growth is a cornerstone of the burgeoning Georgia solar panel manufacturing sector, positioning the state as a leader in the nation’s clean energy transition.

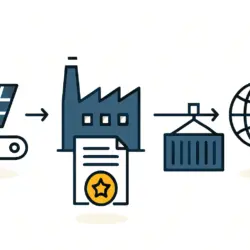

A Fully Integrated Solar Manufacturing Complex

The new Cartersville facility is not just another factory; it’s a pioneering venture. Set to be completed by early 2026, it will house the first fully integrated solar manufacturing complex in the U.S. This means the entire solar panel manufacturing process—from producing ingots and wafers to fabricating cells and assembling finished modules—will occur under one roof.

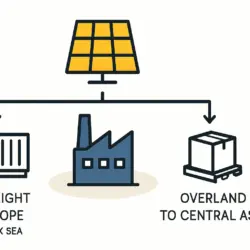

This vertical integration is a game-changer for the domestic supply chain. While key raw materials for solar panels like polysilicon will still be sourced from South Korea, nearly every other step will happen on American soil. The module production lines at Cartersville are already operational, with the ingot, wafer, and cell production lines currently in the commissioning phase. Once fully operational, the facility is expected to bring an additional 2,000 jobs to Bartow County and produce nearly 45,000 solar panels daily.

Qcells’ Long-Term Investment in U.S. Solar Manufacturing

This expansion is part of a broader $2.5 billion investment by Qcells in U.S. solar manufacturing, a commitment significantly spurred by the incentives within the Inflation Reduction Act (IRA). Passed in 2022, the IRA offers substantial tax credits to domestic manufacturers of renewable energy technologies, aiming to boost local production and reduce reliance on imports.

Qcells’ substantial investment, despite recent policy uncertainties in the U.S. market, signals strong confidence in the long-term demand for solar energy. This demand is increasingly driven by the power needs of data centers and the compelling economics of Georgia solar power. Understanding the complete solar panel manufacturing plant cost breakdown reveals the scale and ambition of such an undertaking.

Qcells’ Commitment to Domestic Solar Manufacturing

Qcells’ dedication to expanding its domestic manufacturing capabilities highlights the critical role of renewable energy in the U.S. The company’s investment in Georgia is a major step toward achieving greater energy independence and reducing carbon emissions.

The output from these factories is already earmarked for major projects across the country. For example, ContourGlobal will use panels from these Georgia factories for its new solar plants, and Summit Ridge Energy has secured 800 MW of Qcells panels for its community solar pipeline. This demonstrates a robust demand for American-made solar components and underscores Qcells’ integral role in the broader energy ecosystem, which includes building large-scale projects like the 50-MW solar hybrid plant in California.

By fully integrating its Georgia complex, Qcells is set to enhance production efficiency and meet the soaring demand for solar energy in the U.S., proving the effectiveness of strategic federal incentives in stimulating a resilient domestic manufacturing base.

To learn more about the intricate world of solar panel production, explore our free e-course on solar panel manufacturing.