Disclaimer:

AI-assisted video-content by JvG Technology

Want an offer for solar machines?

Make a request!

Text Version of the Video

Below the information boxes, you will find the text version of the video and further downloads. You will also see the title of the next lesson and when it will be available:

Welcome to this overview of the solar module production process. In this lesson, we'll show you how individual materials are turned into a fully tested, high-quality solar module step by step.

Essential Materials for Production

Every production starts with the right materials. For the main components, we need:

- Glass - The foundation layer

- Encapsulant film - For bonding and protection

- Solar cells - The power-generating core

- Back sheet or second glass - Rear protection layer

- Frame - Aluminum structural support

- Junction box - Electrical connection point

- Sealing materials - For weatherproofing

These components form the foundation of every solar module.

The Complete Manufacturing Sequence

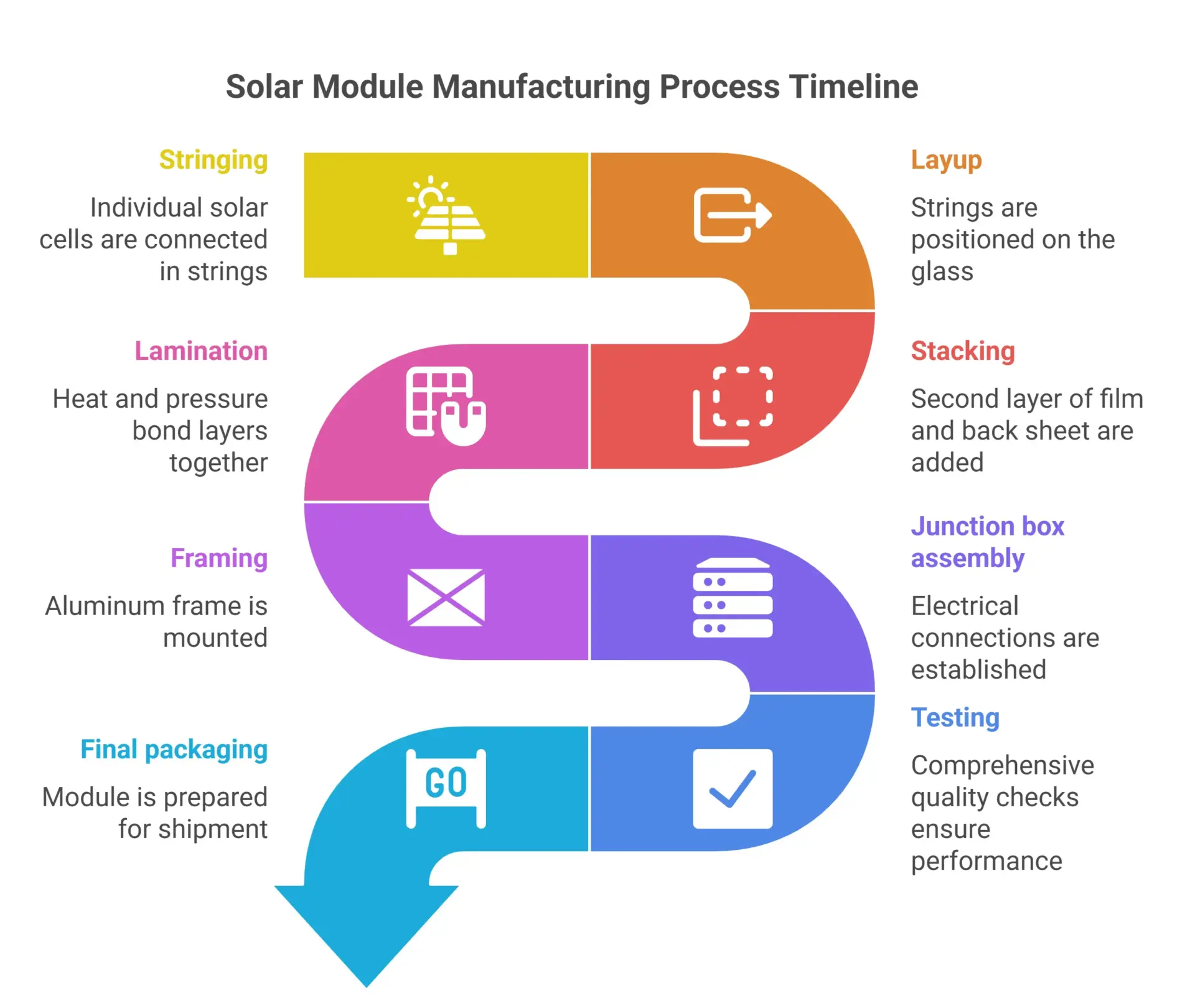

The entire manufacturing process follows a clear sequence from raw materials to the finished solar module:

- Stringing - Individual solar cells are connected in strings to create the electrical circuit

- Layup - Strings are positioned on the glass already covered with encapsulant

- Stacking - Second layer of film and back sheet (or rear glass) are added on top

- Lamination - Heat and pressure permanently bond all layers together

- Framing - Aluminum frame is mounted for structural support

- Junction box assembly - Electrical connections are established

- Testing - Comprehensive quality checks ensure performance

- Final packaging - Module is prepared for shipment

Need Help? Want More Information?

We can help you make a perfect business plan - just click the link below for more information about our paid offerings

Step 1: Building the Module Stack

Preparing the Foundation

The process starts with the bottom glass, the foundation of every solar module. This glass is carefully cleaned and placed on the production line. A layer of encapsulant film, usually EVA or Desert Foil, is then laid over the glass to cushion and seal the cells.

Positioning the Cell Strings

Next, the cell strings arrive from the stringer. They are positioned with millimeter precision on the foil-covered glass to form the electrical layout of the module.

Busing and Connection

The strings are connected together through busing, where the main current paths are created. Every connection must be perfectly aligned to guarantee electrical performance and visual quality.

Final Layer

Finally, another layer of encapsulant film is placed on top to fully embed the cells and protect them during lamination.

Step 2: Lamination Process

Once the module stack is complete with the glass, encapsulant films, solar cells, and the back sheet or rear glass, it moves into the lamination process.

Inside the laminator, vacuum and heat work together to remove any trapped air and permanently bond all layers into one solid structure. The temperature typically rises to around 150°C, while pressure ensures that every layer is sealed tightly.

This step gives the module its:

- Mechanical strength

- Weather resistance

- Long-term stability

When it comes out of the laminator, the module is fully encapsulated and ready for further processing - trimming, framing, and testing for quality.

Step 3: Trimming, Sealing, and Framing

After lamination, the module is still a rough panel. The edges are sealed, but excess material remains.

Trimming

The first step is trimming, where any overlapping film or back sheet is precisely cut away to achieve clean, uniform edges.

Sealing

Next, sealing tape or silicone is applied around the perimeter. This creates a tight moisture barrier and ensures long-term protection against environmental stress.

Frame Installation

Finally, the aluminum frame is mounted. The frame gives the module its final rigidity, defines its dimensions, and makes later handling and installation much easier.

At this stage, the module now looks complete, but it still needs electrical connection, testing, and final inspection before it's ready to leave production.

Read more about our turn key services

Step 4: Visual Inspection and Junction Box Installation

Manual Inspection

Once the module has been framed, it goes through a detailed manual inspection. Trained operators check every surface for:

- Scratches

- Air bubbles

- Visual defects

Even small imperfections can affect the long-term performance or appearance of the module.

Junction Box Attachment

After inspection, the junction box is attached to the back of the module. This box contains the electrical connections that link the module to the solar system.

The contacts are connected using conductive adhesive or soldering, and the box is sealed to protect against moisture. Once cured, the junction box forms the electrical heart of the module, ensuring safe current flow and long-term reliability in the field.

Step 5: Comprehensive Testing

Before any module leaves the factory, it must pass a full series of electrical and mechanical tests.

Flash Test

The first is the flash test - a short burst of artificial sunlight that measures the real electrical performance of the module. This determines its power class and verifies that it meets the rated specifications.

Electroluminescence (EL) Test

Next comes the electroluminescence test or EL test. Here, a special camera detects even the smallest micro-cracks or hidden defects inside the cells that are invisible to the eye.

HiPot Test

Finally, the HiPot test ensures electrical insulation and safety. It checks that no current leaks through the module structure - an essential step for reliability and long-term operation.

Only modules that pass all of these tests continue to labeling and final packaging.

Step 6: Labeling and Final Packaging

Individual Identification

After all tests are completed, each module receives its individual label and serial number. This label contains essential data such as:

- Power rating

- Voltage

- Current

- Manufacturing details

Potting

The next step is potting, a protective sealing process for the junction box. A special resin is poured inside to secure the electrical connections and protect them from moisture and temperature changes.

Final Preparation

Once the potting has hardened, the modules move to final packaging. They are:

- Cleaned thoroughly

- Visually checked one last time

- Stacked properly

- Palletized for shipment

At this point, the modules are complete, fully tested, certified, and ready for installation anywhere in the world.

Understanding the Complete Production Flow

This overview shows how solar module production is a carefully orchestrated sequence of precision steps. Each stage builds on the previous one, and quality control is integrated throughout the entire process.

From the first glass sheet to the finished, fully tested module, every step is designed to ensure:

- Maximum performance

- Long-term reliability

- Consistent quality

- Safe operation

Start Your Solar Production Project

If you're planning a new factory or need support with equipment and setup, feel free to reach out to us at JVG Technology. We are here to help you bring your solar project to life, from initial planning through equipment selection to a fully operational production line.

Read more about our turn key services

Need an offer for machines?

Contact us Now!

I very much impressed by e-lessons. Iam enjoying